Magnetic coupling is an important application of the permanent magnet which mainly uses attractive force between opposite magnetic poles, and hence formed non-contact transmission between internal and external mechanical system without friction and noise.

Characteristics of Magnetic Coupling

- Transform traditional dynamic seal into static sealing and therefore achieve zero leakage transmission of power.

- Transmission of vibration can be avoided, then realize stable running of equipment with non-contact transmission.

- Release over-load protection.

- Simple structure, easy to assemble, debug and maintain.

- Different movement forms are available includes linear movement, rotational movement, or screw composite motion.

- Eliminate pollution.

Classifications of Magnetic Coupling

Magnetic coupling has different classification criteria:

- Can be classified to synchronous type, eddy current type, and hysteretic type based on coupling principle.

- Can be divided into linear type, rotational type, and screw type according to movement form.

- Can be classified as cylinder type and disc type on the base of the structural form.

- Can be fell into intermittently type and combined type as per arrangement of magnet.

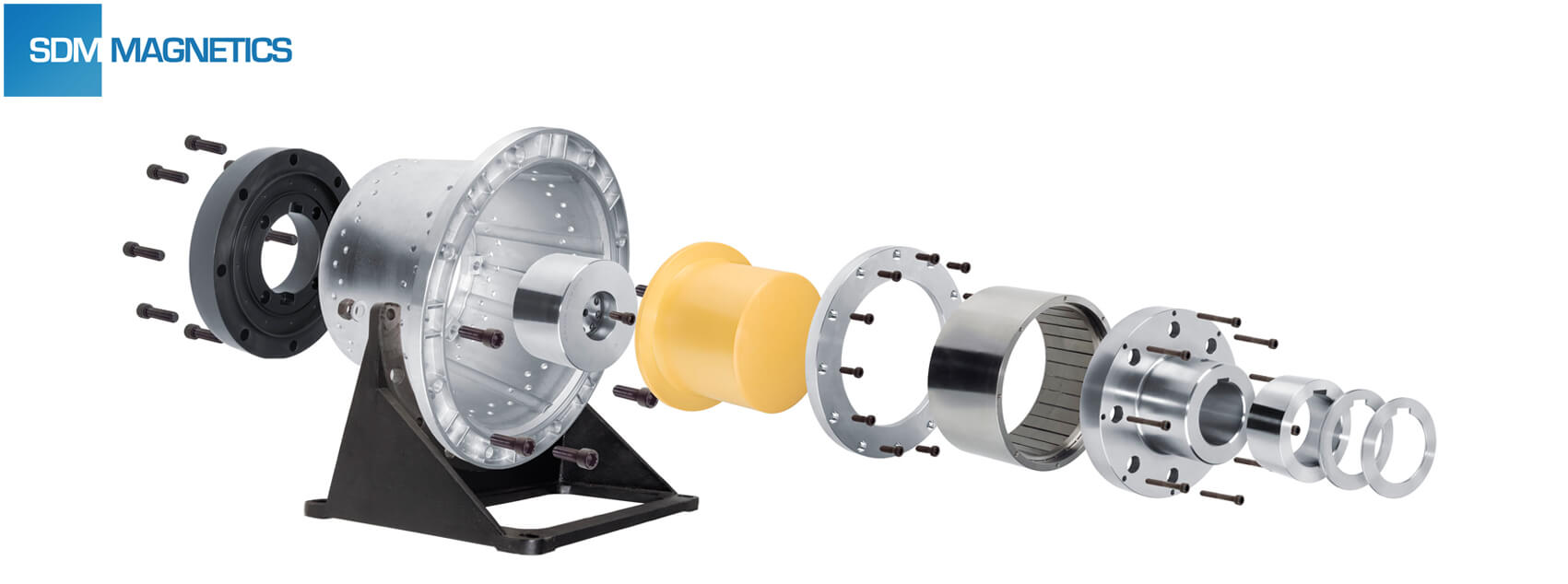

Basic Structure of Magnetic Coupling

Magnetic coupling are mainly consisted of outer rotor, inner rotor, and isolation shell which involves permanent magnet, soft magnetic material, and magnetic shielding material.

Magnets for coupling should possess high enough remanence to provide ideal torque, high enough intrinsic coercivity to prevent demagnetization, and favorable thermal stability. The main function of magnetic shielding material is support and protect the permanent magnet, and magnetic shielding is secondary. Magnetic shielding material needs low permeability to ensure much of magnetic flux travel between a pair of poles. Magnetic shielding material also requires a certain corrosion resistance. Magnet will be assembled on the inner and outer rotor, and rotor should be fabricated by high permeability soft magnetic material to form completely circuit.

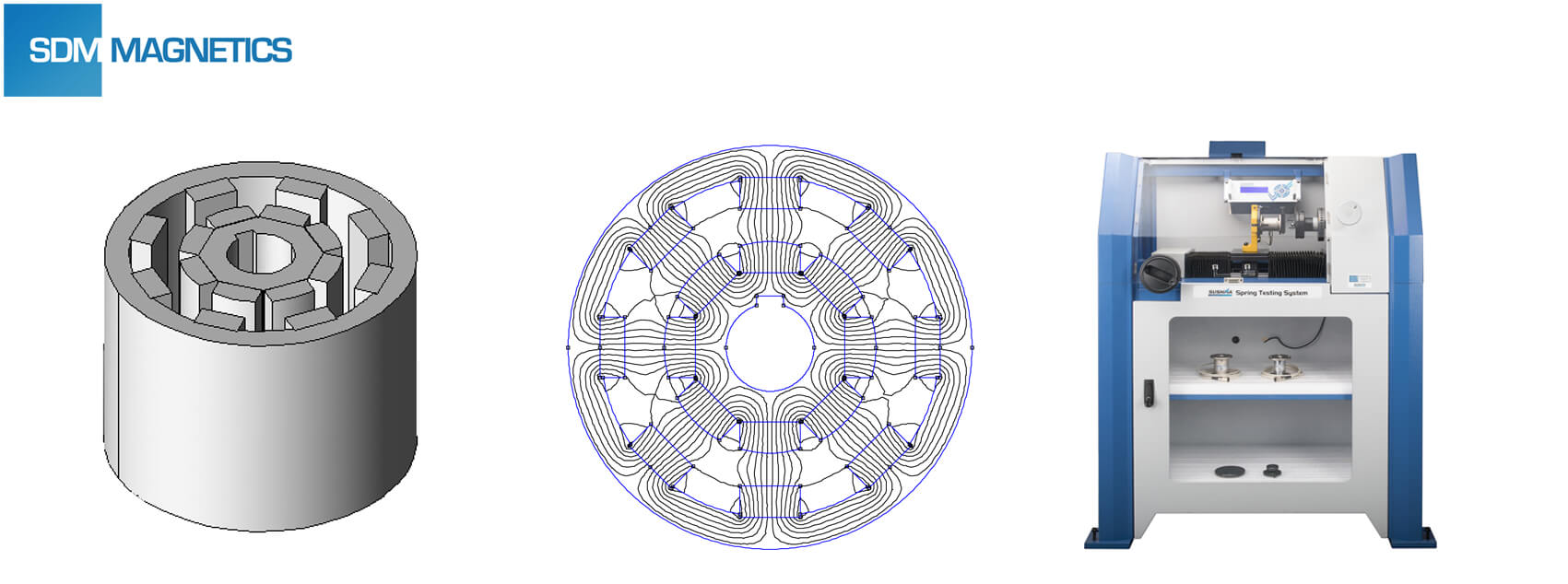

Structural Parameter Optimization of Magnetics Coupling

Magnetic coupling have many structural parameters, and variations of parameters will directly influence the transmission of torque.

- Optimization of magnetic pole number. According to magneto static energy principle, the increase of pole number is propitious to the storage of energy, thus static energy will be released after converted into kinetic energy. However, too many poles mean the higher flux leakage, therefore decrease air gap flux density and corresponding torque. The large effective radius or big air gap needs fewer poles, and little effective radius or small air gap needs more poles.

- Optimization of yoke iron’s thickness. Yoke iron can effectively prevent the external magnetic field. As part of the magnetic circuit system, yoke iron also can change the strength and distribution of flux density, while adjust flux leakage and working condition of the permanent magnetic field. Thin thickness iron will cause the magnetic saturation, then magnetic resistance increases and finally reduce torque.

- Optimization of permanent magnet’s thickness. Magnetic potential of the whole circuit is provided by the permanent magnet. The higher the air gap flux density, the higher the torque. Torque will increase sharply along with the thickness of the permanent magnet within limits. When thickness reaches the certain value, torque no further increase due to magnetic resistance and flux leakage.

July 16, 2019

Boa tarde,

Achei o artigo interessante. Mas…

Preciso saber mais a cerca do tema ”Acoplamento Magnético Entre Pólos Nos Motores de Relutância Variável Comutada”.

January 18, 2022

Hey

I need help to calculate magnet couplings