Owing to its series of advantages, injection molded magnet has been widely used in many areas, such as automotive, electronics, information and automation. Polyphenylene sulfide (PPS) and polyamide (Nylon) are the two most commonly used binder for injection molded magnet.

Advantages of NdFeB PPS Magnet

Most of injection molded NdFeB magnet adopts Nylon as binder, and the magnetic powder loading can achieve 93wt% due to the excellent viscosity of Nylon, however, NdFeB Nylon magnet couldn’t work properly under some special environments, and NdFeB PPS magnet can be used under high temperature, high humidity and corrosive environment rely on below advantages:

- Superior mechanical properties, includerigidity, impact toughness and wear resistance.

- Good thermal ability: The Max. Operating Temperature of NdFeB PPS magnet can reach 180 deg C.

- Water absorbability of PPS is much lower than Nylon.

- Outstanding anti-corrosion ability and solvent resistance.

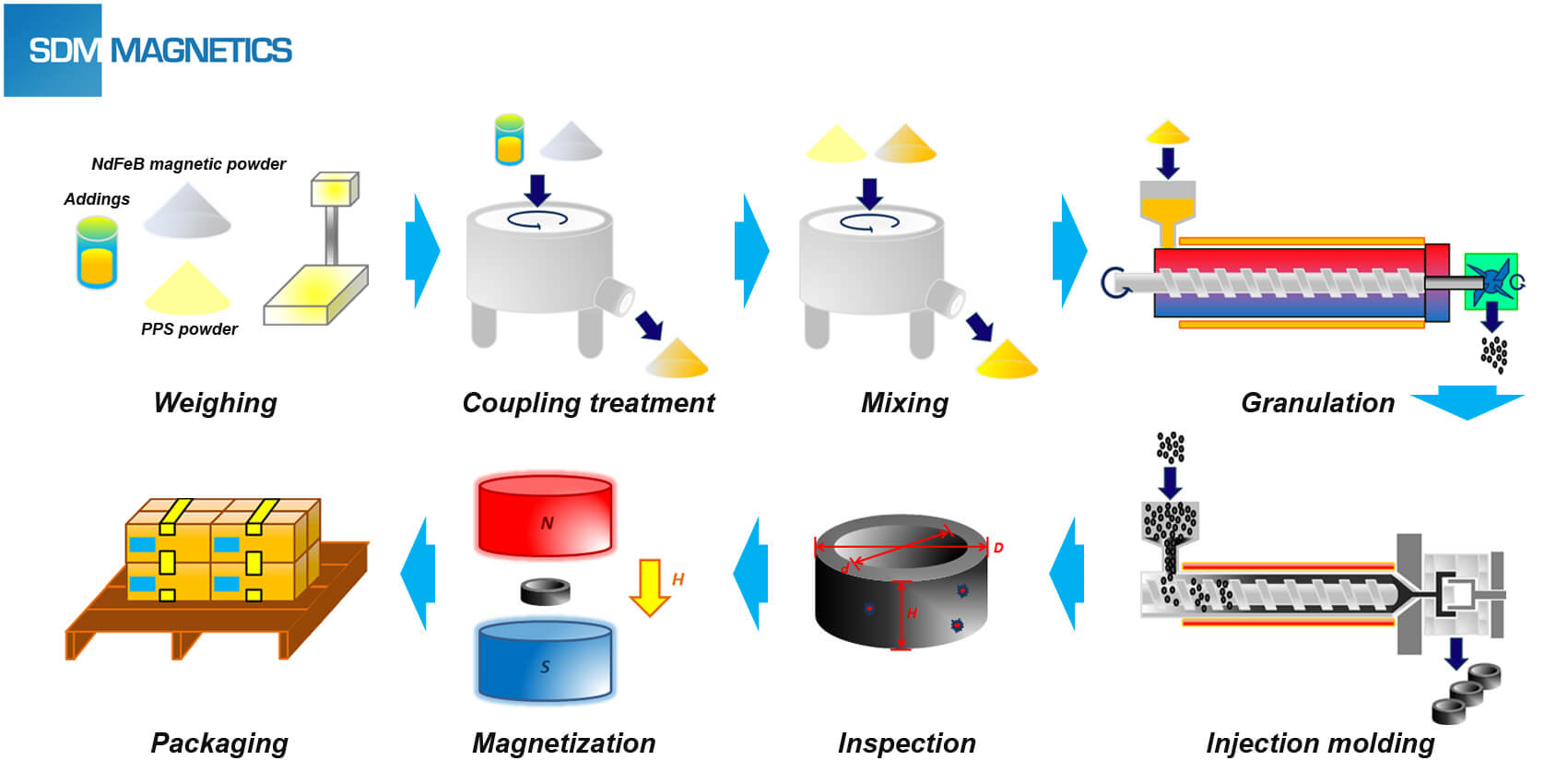

Manufacture Process of NdFeB PPS Magnet

The most difficult task during the manufacture process of NdFeB PPS magnet is granulation process. The compound with enough magnetic properties and workability is the main point to make the ideal NdFeB PPS magnet.

Compound of NdFeB PPS Magnet

Magnetic powder loading of NdFeB PPS compound can’t reach a very high level because of relatively low viscosity under high-temperature processing. How to make NdFeB PPS compound with high loading is always a hot research area in the bonded magnet industry.

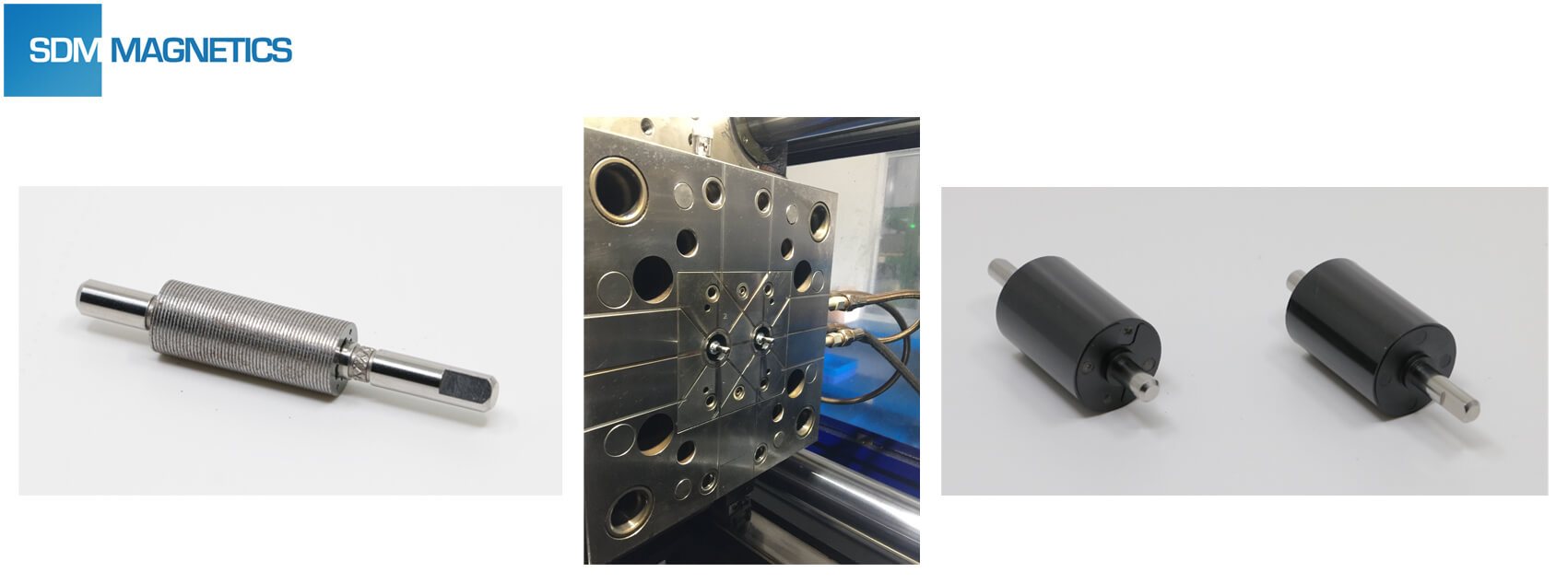

Experience of NdFeB PPS Magnet

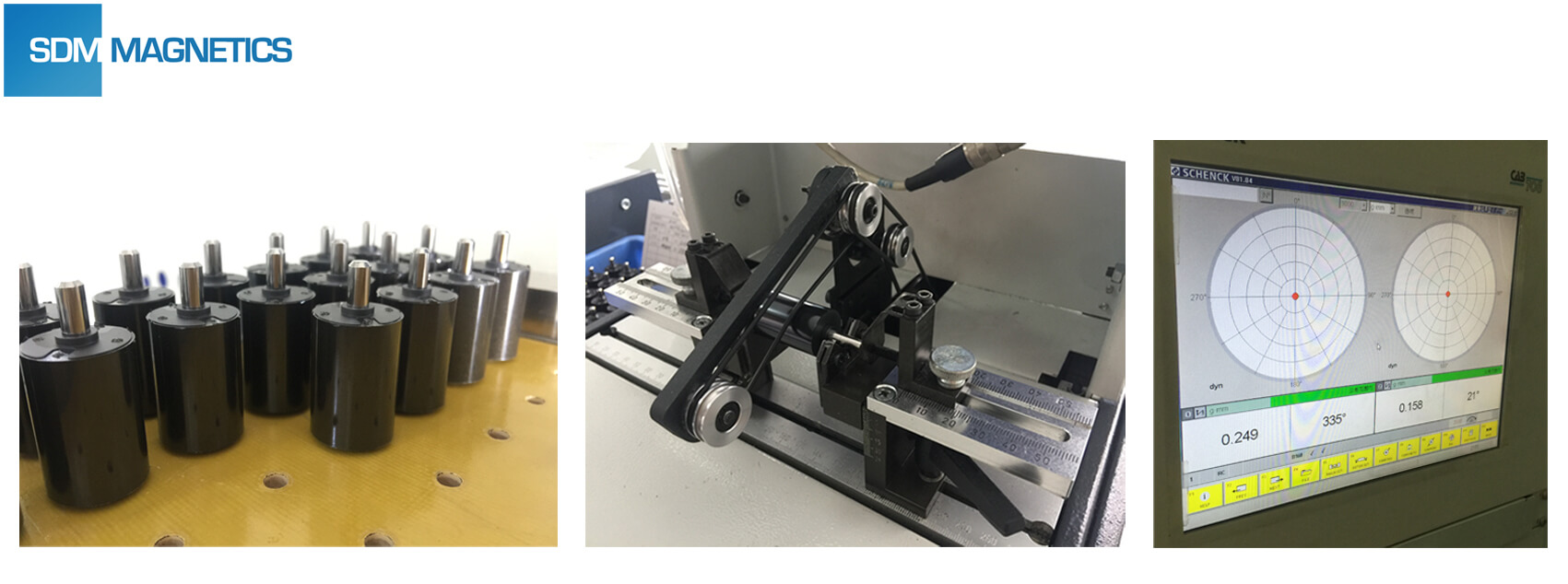

SDM team has collected much useful experience on NdFeB PPS magnet, and related products have been served to the automotive industry.

SDM team is able to complete 100% inspection of dynamic balance performance.