The sufficiently high coercivity will ensure B-H curve in straight line which avoids knee point, and thus decrease open-circuit irreversible flux losses of Neodymium magnets. Once knee point appears, open-circuit irreversible flux losses will inevitably occur when operating point below the knee point due to the Pc changes during run time or influence by the external magnetic field, therefore, aggravates rotating characteristics of the magnetic devices or even stop working. In order to enhance high-temperature operation reliability of the devices, designers are only able to put operating point between remanence and knee point by increasing the size of the magnet which will add costs. Actually, improve room-temperature intrinsic coercivity of Neodymium magnets is regarded as the most effective way to push up kneed point temperature, so high operating temperature is equivalent to high intrinsic coercivity in many application, especially in motors and generators. With the development of wind power generation, energy-saving home appliance and new energy vehicle, long-term operating temperature of the magnet increased to 200 deg C and 220 deg C from 150 deg C, in the meanwhile, room-temperature intrinsic coercivity rose to 40kOe from 21kOe.

The remanence and Max. Energy Products of Neodymium magnet has already been achieved 97.27% and 91.5% of their theoretical values respectively, yet intrinsic coercivity has only reached 12.0% which still has the possibility to substantially improve.

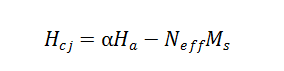

The coercivity mechanism of Neodymium magnet is belong to nucleation type, and its intrinsic coercivity can be described by below formula:

Where Ha and Ms is the magnetocystalline anisotropy field and saturation magnetization of main phase respectively; α and Neff are the parameter closely related to the microstructure of the magnet. α indicate the ratio between actual nucleation field and magneocrystalline anisotropy field, and Neff characterizes reducing effect in intrinsic coercivity caused by internal stray field.

Preparation of high coercivity Neodymium magnets is based on the premise of maintaining Ms, then enhance α and Ha while reduce Neff. The intrinsic coercivity can be further increase by the appropriate introduction of pinning mechanism. The traditional technical path is substitute Nd by Dy/Tb to improve the Ha or adding a small amount of transition metal to optimize microstructure. Dual-alloy technology, grain boundary diffusion (GBD) technology and grain refinement technology are all can be served to the manufacture of high coercivity Neodymium magnets.