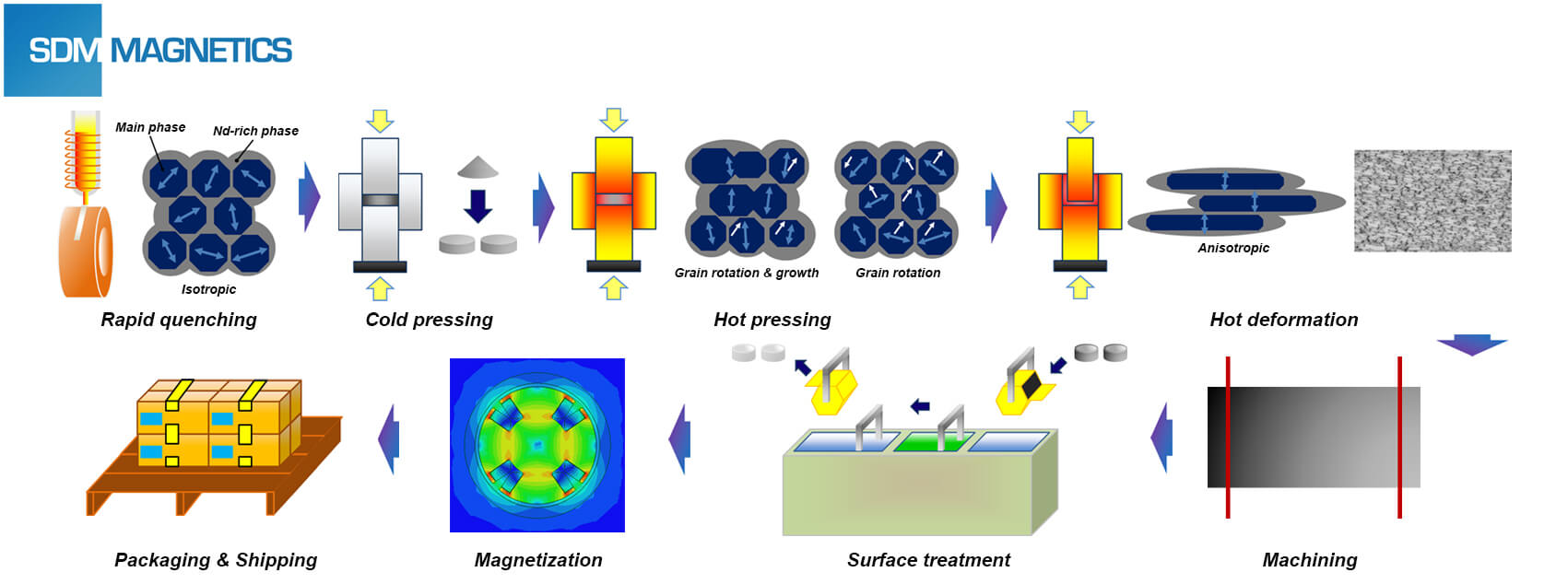

The (BH)max value gap between bonded Neodymium magnet and sintered Neodymium magnet is relatively huge, then high abundant rare-earth permanent magnet and hot pressed magnet have long been considered as the effective solution to fill this gap. Manufacturing process of hot pressed Neodymium magnet is significantly different from bonded Neodymium magnet and sintered Neodymium magnet. In reality, hot deformation process is another path to produce radially oriented ring magnet. Hot deformation process can generate anisotropy along the radial vector without applying radially orientation magnetic field, which entirely unlike conventional powder metallurgy process. Randomly oriented crystals go through preferential grain growth and rotation continuously hot deformation process, then results in the full density nanocrystalline structure with excellent magnetic performance in the radially direction.

Manufacturing Process of Hot Pressed Magnet

Magnetic Properties of Hot Pressed Magnet

| Grade |

Remanence Br |

Coercivity Hcb |

Intrinsic Coercivity Hcj |

Max. Energy Product (BH)max |

||||

| T | kGs | kA/m | kOe | kA/m | kOe | kJ/m3 | MGOe | |

| 50M | 1.40-1.45 | 14.0-14.5 | ≥1043 | ≥13.1 | ≥1114 | ≥14 | 374-406 | 47-51 |

| 45M | 1.33-1.37 | 13.3-13.7 | 954-1058 | 12.0-13.1 | ≥1273 | ≥16 | 318-366 | 40-46 |

| 42M | 1.29-1.32 | 12.9-13.2 | 939-1034 | 11.8-13.0 | ≥1273 | ≥16 | 302-342 | 38-43 |

| 48H | 1.35-1.40 | 13.5-14.0 | 1042-1114 | 13.1-13.6 | ≥1432 | ≥18 | 342-366 | 43-36 |

| 45H | 1.32-1.35 | 13.2-13.5 | 954-1042 | 12.5-13.1 | ≥1432 | ≥18 | 318-342 | 40-43 |

| 42H | 1.29-1.32 | 12.9-13.2 | 931-1010 | 12.2-13.1 | ≥1432 | ≥18 | 286-326 | 36-41 |

| 40H | 1.26-1.29 | 12.6-12.9 | 931-1010 | 11.7-12.7 | ≥1432 | ≥18 | 286-318 | 36-40 |

| 45SH | 1.32-1.35 | 13.2-13.5 | 954-1042 | 12.5-13.1 | ≥1592 | ≥20 | 318-342 | 41-44 |

| 42SH | 1.29-1.32 | 12.9-13.2 | 962-1042 | 12.2-13.1 | ≥1592 | ≥20 | 302-326 | 38-41 |

| 40SH | 1.26-1.29 | 12.6-12.9 | 939-1010 | 11.8-12.7 | ≥1592 | ≥20 | 286-318 | 36-40 |

| 38SH | 1.22-1.26 | 12.2-12.6 | 923-986 | 11.6-12.4 | ≥1592 | ≥20 | 278-310 | 35-39 |

| 35SH | 1.18-1.23 | 11.8-12.3 | 891-962 | 11.2-12.1 | ≥1592 | ≥20 | 246-286 | 31-36 |

| 38UH | 1.22-1.26 | 12.2-12.6 | 907-986 | 11.4-12.4 | ≥1989 | ≥25 | 278-318 | 35-40 |

| 35UH | 1.18-1.23 | 11.8-12.3 | 891-962 | 11.2-12.1 | ≥1989 | ≥25 | 246-286 | 31-36 |

- The above-mentioned data of magnetic properties and physical properties are given at room temperature.

- The max working temperature of magnet is changeable due to length-diameter ratio, coating thickness and other environment factors.

Advantages of Hot Pressed Magnet

- (BH)max value on the radial direction can range from 240 to 400kJ/m3 and maximum operating temperature can achieve 180 degrees Celsius.

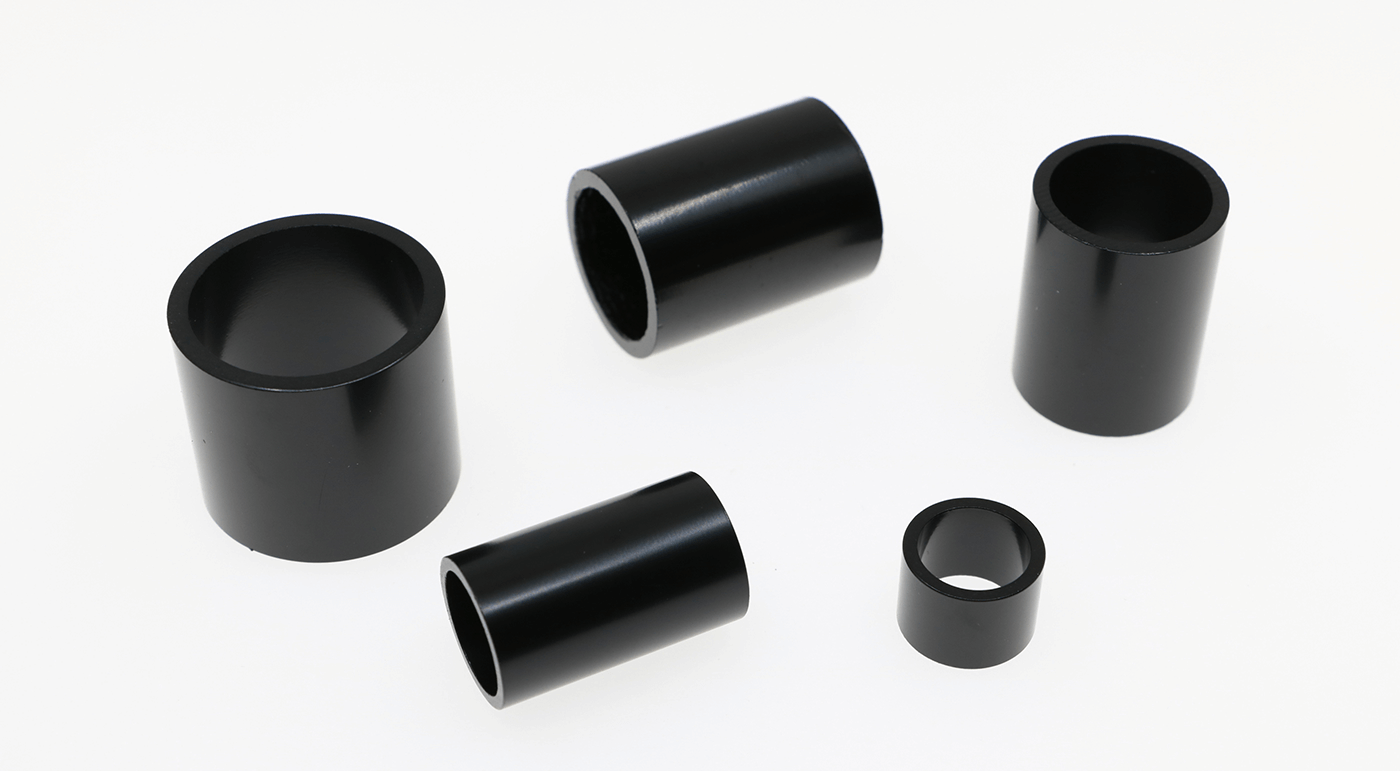

- Hot pressed magnet is more tailored for the small-sized, high L/D ratio, and thin-walled radially oriented ring magnet in comparison with traditional sintered magnet.

- Nanocrystalline structure, lower Nd-rich phase content, and higher density offer excellent corrosion resistance to hot pressed magnet.

- Free of cracking and deformation caused by internal stress and thereby exhibits much better mechanical strength.

- Rare earth element amounts in hot pressed magnet are 2% lower than sintered magnet under the same magnetic performance requirement. In the meanwhile, hot pressed magnet needs less heavy rare earth elements (HREEs) to enhance thermal stability. Furthermore, hot deformation process a type of near-shape technology which has a relatively higher raw material utilization rate.

- Magnetic field strength waveform is only determined by magnetization fixture.

- Hot pressed magnet has superior waveform homogeneity and deviation angle, then more propitious to increase motor performance.