Magnets can be combined with different types of functional material to form specific magnetic assemblies such as pot magnet. For plastic integrated magnet, multiple components can be integrated through the injection molding process even each component has its own property. Magnet embedded in the plastic could be undamaged under external impact, also be given excellent dimensional accuracy and superior cost advantage in the production of high quantity complex assemblies, thus capture customers from civilian use to automotive applications.

Manufacturing Process of Plastic Integrated Magnet

Plastic integrated magnet can be implemented by insert molding, over molding, ultrasonic welding or some other options, then concrete process is determined by the relevant technical specifications.

Insert Molding:

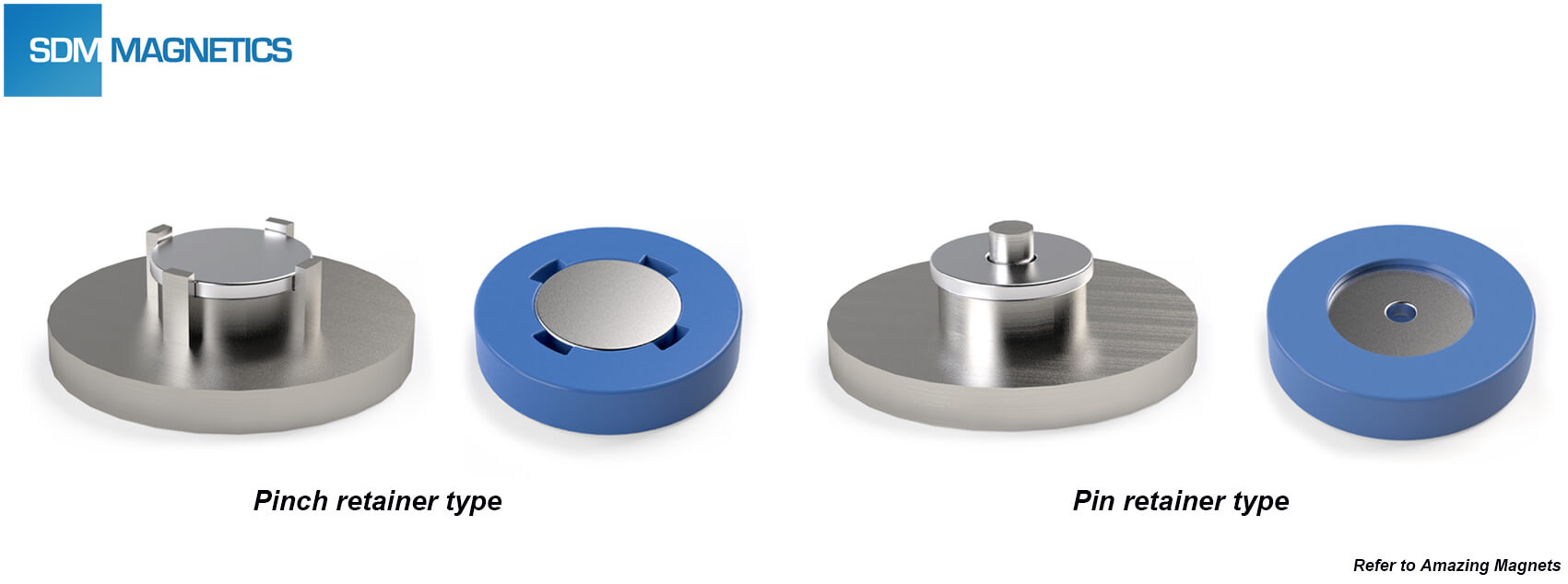

For insert molding process, magnets are embedded into the plastic part. Unmagnetized permanent magnet is inserted into the cavity of the mold before injection molding which allows the molten plastic material to flow around the magnet. Besides the pretty high molding temperature, molten plastic is also injected at high pressure, thus require magnets must be held without movement during the injection molding process. Actually, there are two solutions for holding the magnet: pinch retainer type and pin retainer type.

SDM has collected many experience insert molding type plastic integrated magnet.

Over Molding:

Over molding is the most conventional method to obtain fully encapsulated magnets and thus ensure magnets can be exposed under the harsh environment. The over molding technology involves two separate moulds and utilize one of moulds to make plastic part with cavity to place the magnet. Insert magnet into first plastic part, then place semi-finished assembly into another mould, thus molten plastic cover the magnet to form the second plastic part and fusing with the first plastic part in the meanwhile. Actually, you can find obvious weld line in this kind of plastic integrated magnet.

Ultrasonic Welding:

Ultrasonic welding is another technology to fully encapsulate the magnet which two pieces of plastic part assemble with magnet and fuse together by high-frequency vibration generated by ultrasonic welding machine.

Other Options:

Other options include button type, screw type and melt rivet type.

February 25, 2022

Hi there,

Very interesting information on your website. Thank you/.

I am an engineer designing something that must include a magnet. I would like your help with a quetsion.

The magnets I will be using are 3 and 5 mm diameter with a thickness of 1mm. I want to encapsulate these into Polystyrene parts by suing ultrasonic welding. Basically I have designed a circumference that the magnet will be placed into ( the plastic circumference is about 0.5mm taller than the magnet. Then I will use an Ultrasonic horn that will press this excess plastic over the magnet to encapsulate it. Will the magnet survive the vibrations of the Ultrasonic process? I am concerned that it may shatter. The magnets I am using are Neodymium N52 disk type.

Thanks in advance for your feedback.

Kind Regards

Paskalis Gogoudis