Magnetic assemblies refer to the tool or system which incorporates permanent magnetic material and different kind of non-magnetic together. Magnetic assembly can provide stronger pull force to the ferromagnetic load or exhibit an ideal magnetic field in a specific space owing to the presence of the magnetic circuit.

Advantages of Magnetic Assemblies

Enhancing Mechanical Strength

Inherently brittle is always a serious problem to the application of sintered Neodymium magnet, sintered Samarium Cobalt magnet, and sintered ferrite magnet. Repetitive mechanical shock will cause magnets to lose volume, thus lead to the certain deterioration in magnetic strength. Non-magnetic housing like ferrous metal, non-ferrous metal, or plastic protects the magnets from damage. Besides, non-magnetic material also contributes to a mechanically stronger magnetic system. The totally enclosed solutions like overmolding, ultrasonic welding, or laser welding, are technically feasible to fulfill harsh environmental requirements.

Enhancing Magnetic Strength

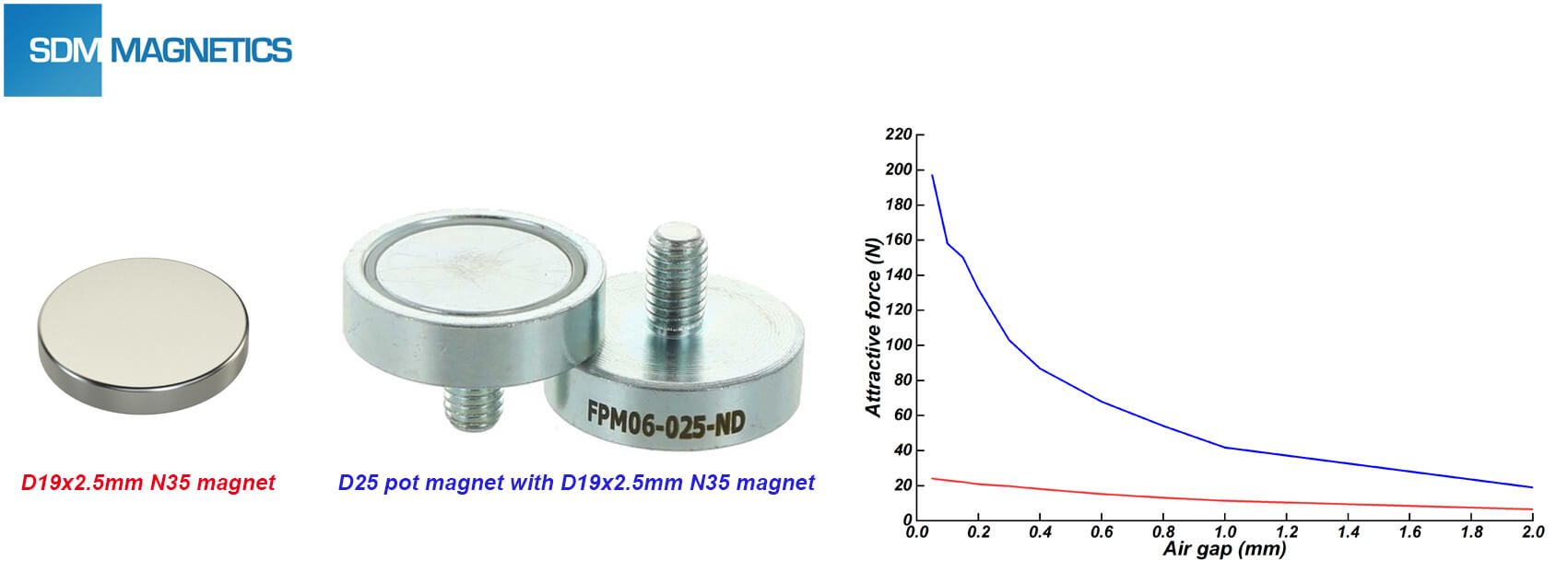

In addition to enhance mechanical strength, the most important feature of magnetic assembly is definitely increasing magnetic strength. Magnetic assemblies are able to generate much higher magnetic strength due to the flux conducting parts are normally an integral part of the entire magnetic circuit. Flux conducting parts can significantly increase the magnetic flux and guide it to the specific region. Moreover, magnetic assemblies also exhibit greater cost advantage under the same requirement of magnetic strength. Both pot magnet and Halbach array are the most persuasive products for this characteristic. When a magnet is served in the pot magnet, the pull force will be several times higher compared to it used alone. As for Halbach array, magnetic field in the specific region can even exceed the remanence of the permanent magnetic material itself.

Mounting Mechanisms for Holding Applications

Non-magnetic parts in the magnetic assemblies typically possess mounting options for distinct holding applications.

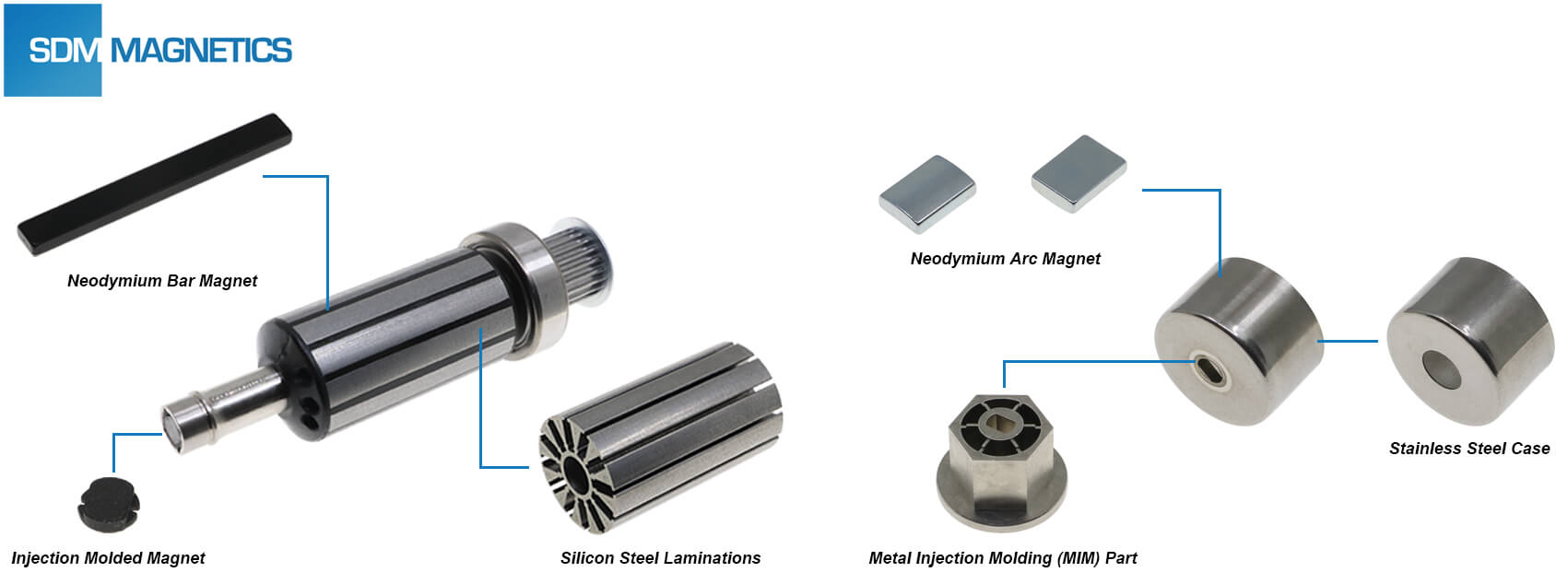

SDM Magnetics specializes in the design and cost optimization of conventional magnetic assemblies by simulation and experience. Then demand for custom magnetic assemblies is growing steadily and this requires expertise in material choice and fabrication methods. SDM Magnetic is capable to produce all kinds of permanent magnetic materials, soft magnetic materials, and metal injection molding (MIM) parts and, more importantly, SDM Magnetics has been always pursuing integration capability of different materials to provide whole magnetic assembly solution to our customers. Besides industrial applications, SDM Magnetics is also keen to be involved in civilian magnetic assembly project.