Neodymium pot magnet is the pot magnet made of sintered Neodymium magnet. Neodymium pot magnet is built with axially magnetized countersunk magnet, ring magnet, or disc magnet embedded in the steel shell. Steel shell can protect brittle Neodymium magnet from cracking or chipping during repeating impact. In the meanwhile, an integral closed magnetic circuit will be formed once Neodymium cup magnet attached to ferromagnetic surface, then exhibit strong vertical pull force which much more powerful than the same sized pure magnet. The pull force of conventional Neodymium mounting magnet ranges from 1kg to 480kg. It occupies a considerable share in magnetic assemblies’ market. Typical applications include heavy duty holding, mounting, and fixing purposes in offices, warehouses, classrooms, and workstations.

Product Classifications of Neodymium Pot Magnet

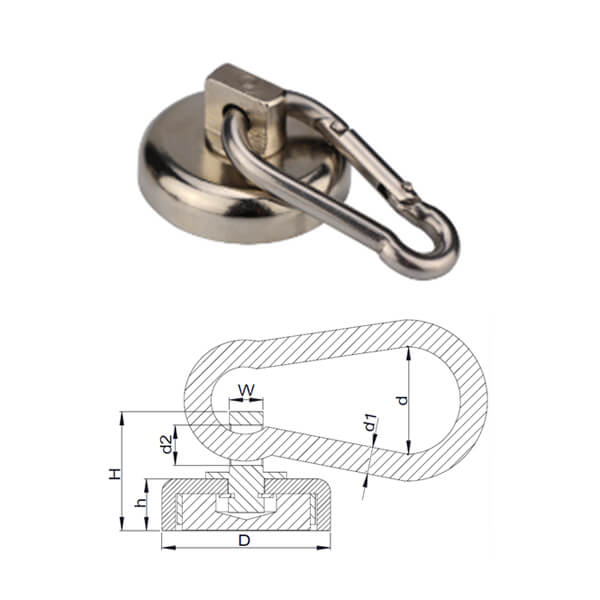

Structural Optimization of Neodymium Pot Magnet

As a typical magnetic assembly for holding purpose, pull force is the cardinal parameter to the pot magnet. Unlike electromagnet or permanent magnetic lifter, pot magnet did not have uniform product specification and testing method. The initial design reserved enough design margin to meet different application scenarios and their structures have relatively large optimization space. Take conventional D25 series as an example, pull force of the original and updated design is 245N and 220N, both of which are higher than the nominal standard of 215N. Thereby, its cost will significantly decrease via reducing thickness of sintered Neoymium magnet. Finite Element Analysis (FEA) results indicate that magnetic flux leakage is serious in the original design that means the magnet is too thick to the steel shell.