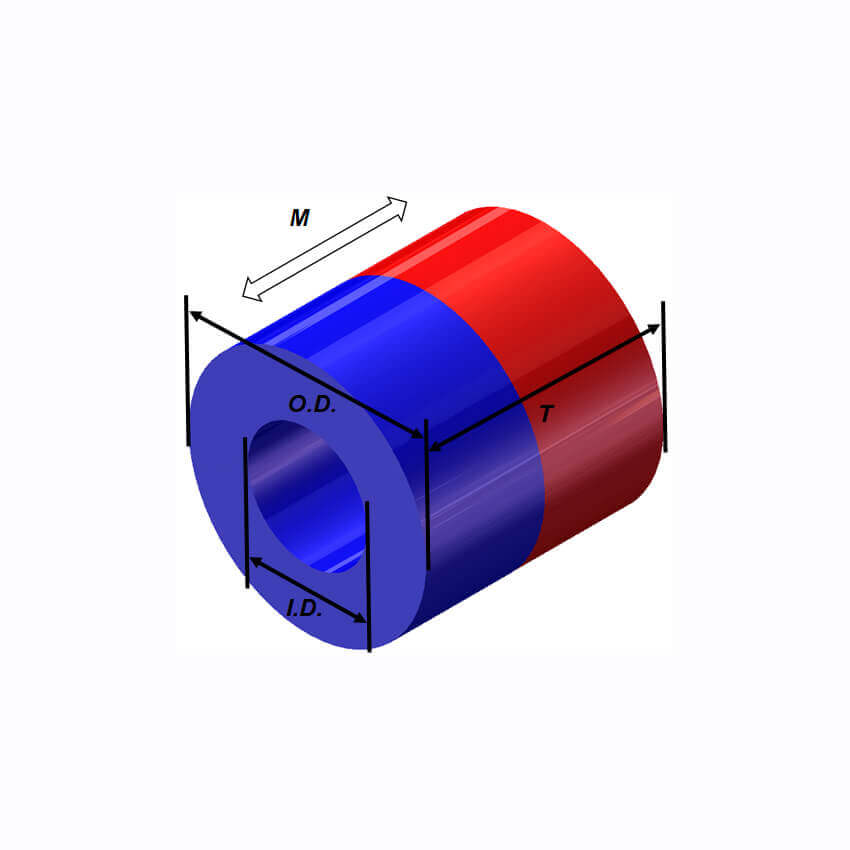

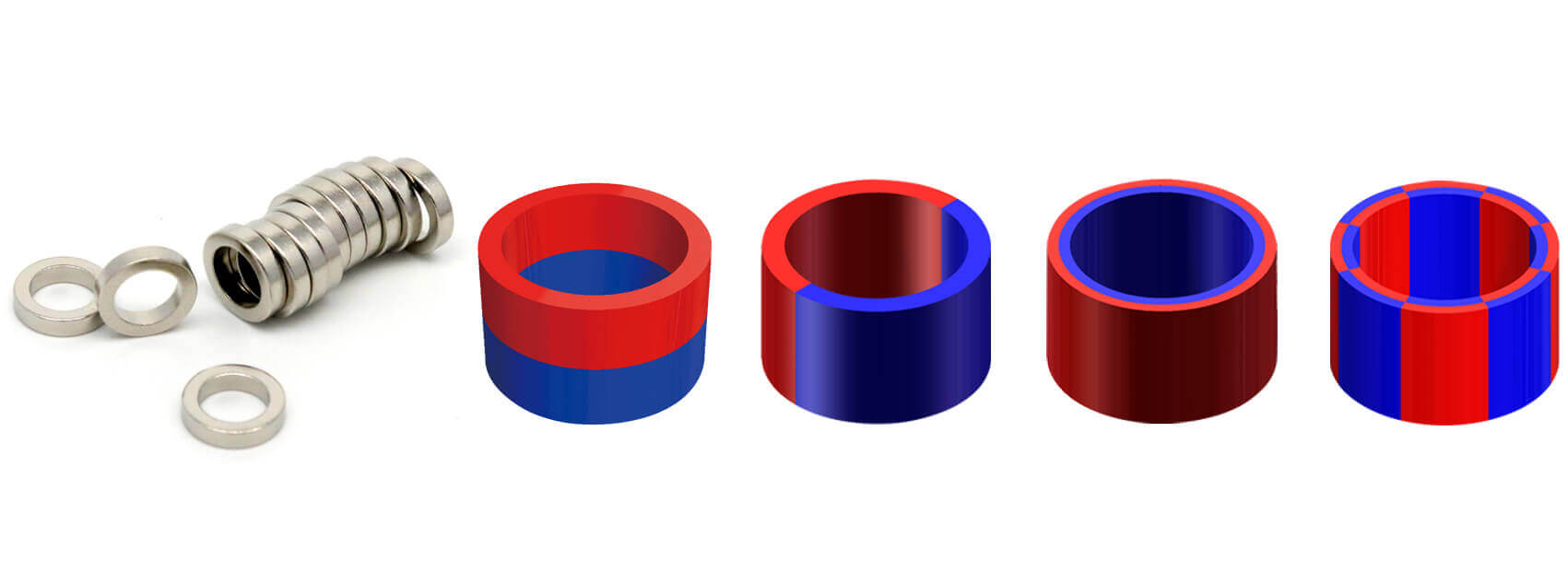

Neodymium magnets are manufactured on the basis of Nd-Fe-B alloys and sintered Neodymium magnets have the highest (BH)max value among all of commercially available permanent magnets. Neodymium ring magnets are circular in shape with a concentric hole inside it. Magnet ring can be divided to pure ring or countersunk ring based on the detailed shape of the inner hole. Neodymium ring magnet should be measured by outer diameter (O.D.), inner diameter (I.D.), and thickness (T). Similar to Neodymium disc magnet, ring shaped magnet can be magnetized with its N pole and S pole opposite flat end surfaces or diametrically magnetized so as to the N pole is on one curved side and the S pole is on opposite curved side. Besides the conventional axially magnetized or diametrically magnetized magnets, radially oriented ring magnet is also available in SDM. In addition, Neodymium magnets are easily corrode under humid condition and are necessary to cover with a protective coating.

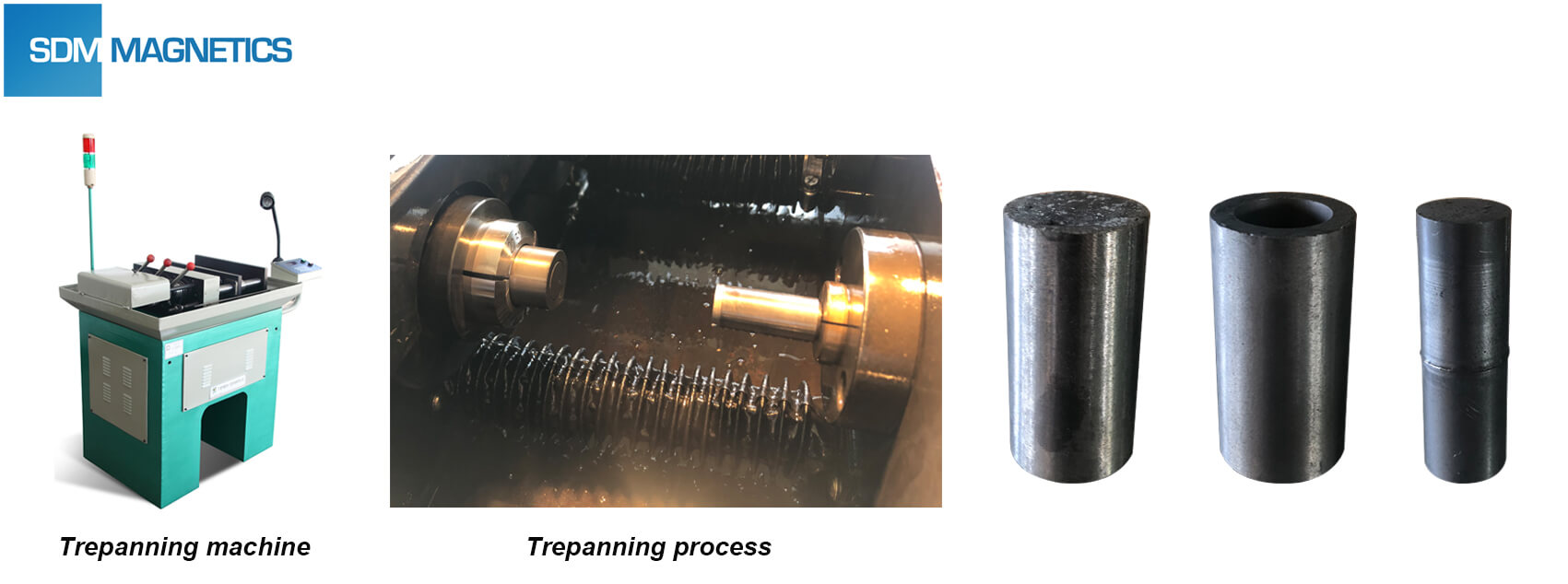

Machining Process of Neodymium Ring Magnet

It is hard for sintered Neodymium magnet to directly achieve required shape and dimensional accuracy at one time due to the technical limitations of magnetic field orientation molding process, then machining process of Neodymium magnet blank is unavoidable. As a typical cermet material, sintered Neodymium magnet is considerable hard and brittle, therefore, there are merely cutting, drilling, and grinding can be served for its machining process among conventional machining technology. 4mm is commonly treated as the critical dimension of ring magnet’s inner hole. It is necessary to select trepanning process when inner hole larger than 4mm. As the by-product in trepanning process, trepanned core can be utilized to manufacture other suitable magnet and thus significantly enhance material utilization ratio.

Magnetic Moment Calculator of Neodymium Ring Magnet

Notes:

- For Neodymium ring magnet, either magnetic moment or magnetic flux are more convincing in comparison with surface gauss value.

- Magnetic moment calculators adapt to non-coating and non-chamfer magnet.

- Recoil permeability μrecof sintered Neodymium magnet is 1.05.

- The calculation results are merely for reference.