Research hotspot of Samarium Cobalt magnets include high performance SmCo magnet, temperature compensated SmCo magnet, and ultra high temperature SmCo magnet. The primary difference between ultra high temperature SmCo magnet and conventional Sm(Co, Cu, Fe, Zr)z magnets is the content of Samarium, Cobalt, and Iron. The αHcj value of conventional Sm(Co, Cu, Fe, Zr)z magnets are relatively high, then coercivity declining rapidly with increasing temperature and Maximum Working Temperature Tw is only 300 degrees Celsius. While ultra high temperature SmCo magnets is a type of permanent magnet with relatively low temperature coefficient of intrinsic coercivity αHcj. It is developed by adjusting the composition and process parameters of conventional Sm(Co, Cu, Fe, Zr)z magnets.

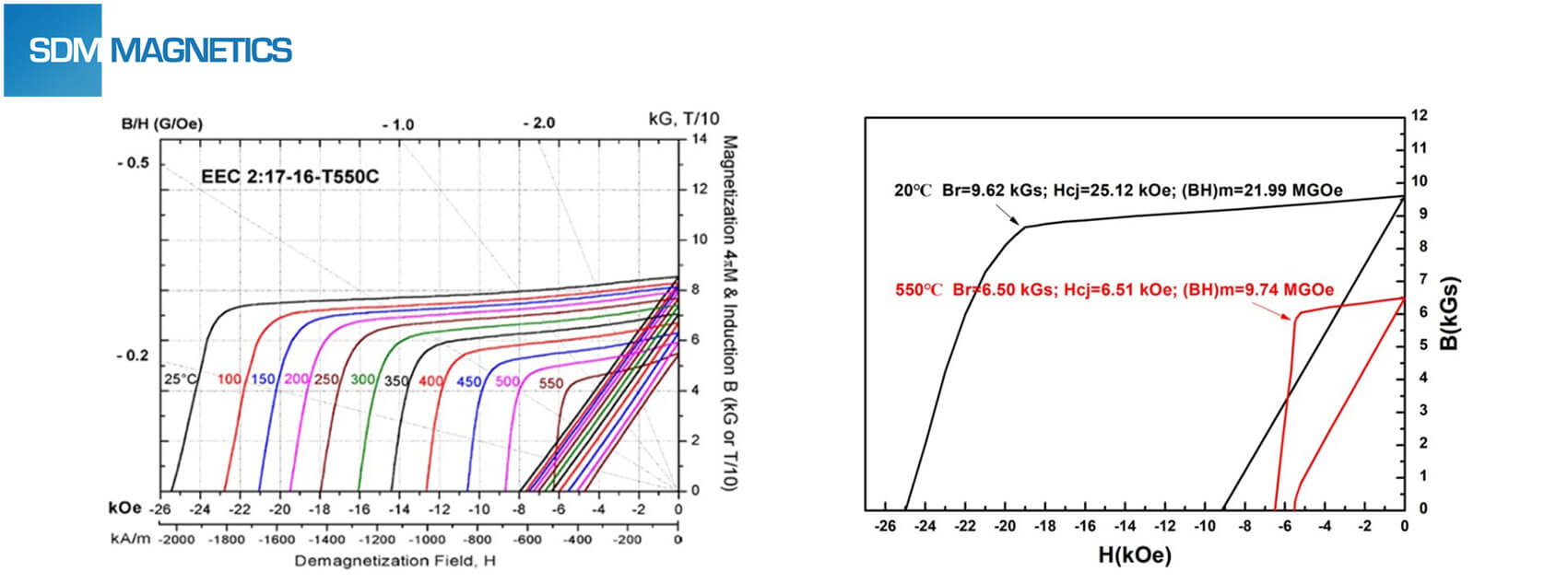

Thermal stability of the permanent magnets is essentially containing double definitions. The first is temperature coefficient of remanence αBr should have low enough absolute value, then magnetic flux change little in the range from room temperature and high temperature. Another definition is irreversible flux loss of open circuit should be low enough. Tw is subordinate to the second definition which request magnets have high enough room temperature intrinsic coercivity Hcj and low αHcj. The combined effect of these two parameters can make Hcj maintains a higher value under high temperature and thus avoid knee point appears in the second quadrant. A linear B-H curve in the second quadrant is critical for all dynamic applications, especially motors. Many studies have indicated that decrease absolute value of αHcj could enhance Tw efficiently in comparison with improving room temperature Hcj when composition is basically determined. Studies have also showed αHcj is relating to the dimension of cellular structure in Sm2(Cu, Cu, Fe, Zr)17. The αHcj value reduces with the reduction of the cellular structure’s dimension. The higher the Samarium and Cobalt content, the more the Sm(Co, Cu)5 cell boundary phases, thus beneficial to form fine cellular structure and reduce temperature coefficient of intrinsic coercivity. For ultra high temperature SmCo magnet, B-H curves in the whole temperature range from 25 to 550 degrees Celsius are shown as line without knee point. SDM has already mastered mass production of ultra high temperature SmCo magnet by optimizing multi-stage heat treatment process and building optimum cellular structure.