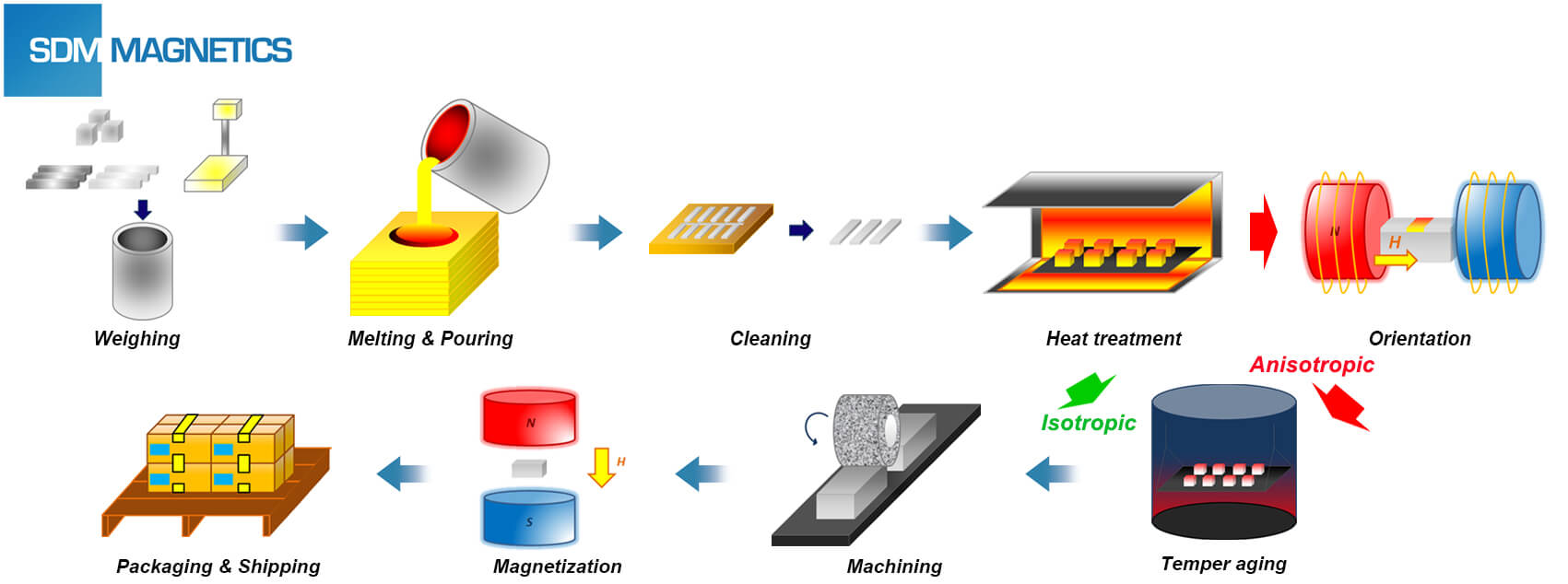

The majority of AlNiCo magnets are belonging to cast type and AlNiCo 5 is the most frequently used grade among them. Cast AlNiCo magnet is produced by common foundry processes. Molten AlNiCo alloys with different chemical composition are melted by induction furnace and poured into the resin bonded sand molds, then solidified material with a rough surface will process heat treatment and cooling process. Cast AlNiCo magnet can offer slighter higher magnetic performance in comparison with sintered AlNiCo magnet. Cast AlNiCo magnet can be divided to the isotropic form and anisotropic form base on whether apply the orientation magnetic field during the cooling process. The majority of cast AlNiCo magnet are anisotropic magnet to fully enhance magnetic properties. Therefore, AlNiCo blank will be machined to exact geometry and tolerance after underwent heat treatment process.

Manufacturing Process of Cast AlNiCo Magnet

Magnetic Properties of Cast AlNiCo Magnet

| Grade |

Remanence Br |

Coercivity Hcb |

Max. Energy Product (BH)max |

Temperature Coefficient %/℃ |

Curie Temperature | Max. Operating Temperature | MMPA Standard | ||||

| mT | Gs | kA/m | Oe | kJ/m3 | MGOe | Br | Hcj | ℃ | ℃ | ||

| LN10 | 600 | 6000 | 40 | 500 | 10 | 1.20 | -0.02 | -0.03 | 810 | 450 | AlNiCo3 |

| LNG12 | 700 | 7000 | 44 | 550 | 12 | 1.50 | -0.02 | -0.03 | 810 | 450 | AlNiCo2 |

| LNG13 | 680 | 6800 | 48 | 600 | 13 | 1.63 | -0.02 | -0.03 | 810 | 450 | |

| LNG18 | 900 | 9000 | 48 | 600 | 18 | 2.25 | -0.02 | -0.03 | 850 | 450 | AlNiCo4 |

| LNG37 | 1200 | 12000 | 48 | 600 | 37 | 4.63 | -0.02 | -0.03 | 860 | 525 | AlNiCo5 |

| LNG40 | 1250 | 12500 | 48 | 600 | 40 | 5.00 | -0.02 | -0.03 | 860 | 525 | |

| LNG44 | 1250 | 12500 | 52 | 650 | 44 | 5.50 | -0.02 | -0.03 | 860 | 525 | |

| LNG52 | 1300 | 13000 | 56 | 700 | 52 | 6.50 | -0.02 | -0.03 | 860 | 525 | AlNiCo5DG |

| LNG60 | 1330 | 13300 | 60 | 750 | 60 | 7.50 | -0.02 | -0.03 | 860 | 525 | AlNiCo5-7 |

| LNGT18 | 580 | 5800 | 90 | 1130 | 18 | 2.25 | -0.02 | -0.03 | 860 | 550 | AlNiCo7 |

| LNGT28 | 1000 | 10000 | 58 | 720 | 28 | 3.50 | -0.02 | -0.03 | 860 | 525 | AlNiCo6 |

| LNGT32 | 800 | 8000 | 100 | 1250 | 32 | 4.00 | -0.02 | -0.03 | 860 | 550 | AlNiCo8 |

| LNGT38 | 800 | 8000 | 110 | 1380 | 38 | 4.75 | -0.02 | -0.03 | 860 | 550 | |

| LNGT44 | 850 | 8500 | 120 | 1500 | 44 | 5.50 | -0.02 | -0.03 | 860 | 550 | |

| LNGT48 | 900 | 9000 | 120 | 1500 | 48 | 6.00 | -0.02 | -0.03 | 860 | 550 | |

| LNGT60 | 950 | 9500 | 110 | 1380 | 60 | 7.50 | -0.02 | -0.03 | 860 | 550 | |

| LNGT72 | 1050 | 10500 | 112 | 1400 | 72 | 9.00 | -0.02 | -0.03 | 860 | 550 | AlNiCo9 |

| LNGT88 | 1100 | 11000 | 115 | 1450 | 88 | 11.00 | -0.02 | -0.03 | 860 | 550 | |

| LNGT36J | 700 | 7000 | 140 | 1750 | 36 | 4.50 | -0.02 | -0.03 | 860 | 550 | AlNiCo8HC |

|

|||||||||||