Parylene is the common name of Poly-para-xylylene which was prepared by the researcher in University of Manchester in 1947. Parylene first applied to U.S military and aerospace industry after Union Carbide prepared parylene thin film by the deposition process. Nowadays, parylene coating are widely used in various areas like parylene coated magnet due to the development of automotive vapor deposition equipment. The most common types of parylene are Parylene N and Parylene C.

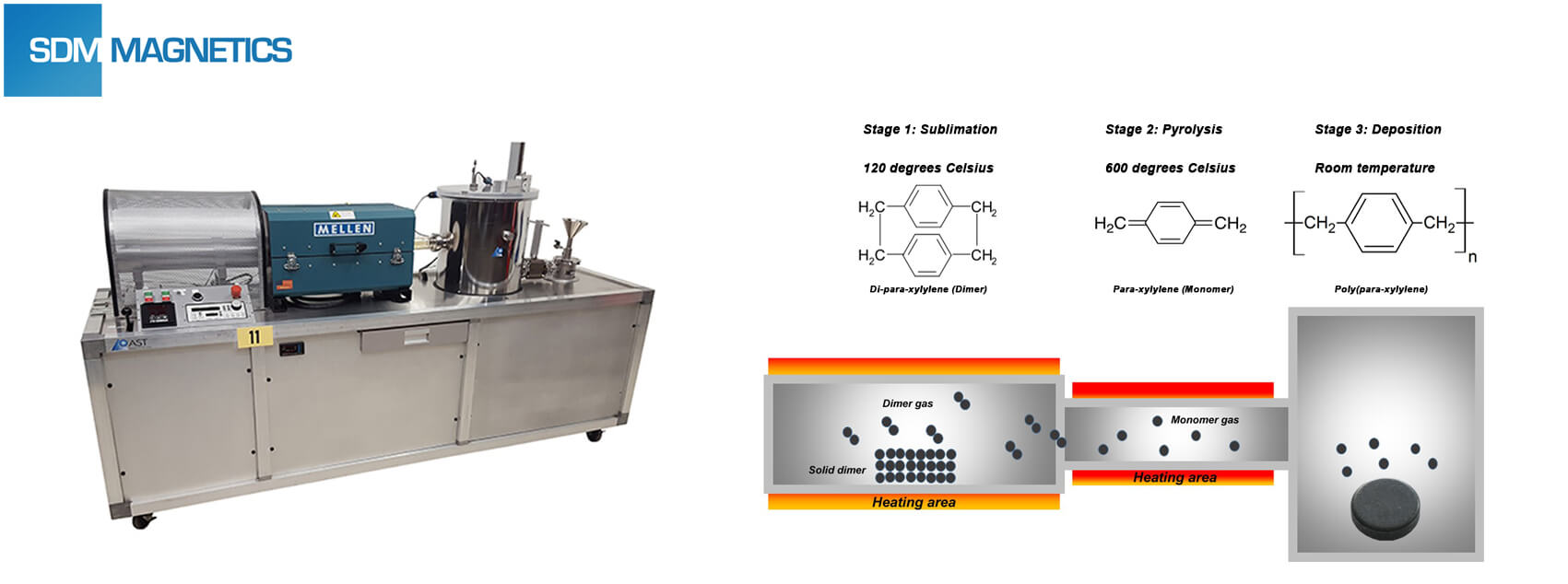

Chemical Vapor Deposition (CVD) Process of Parylene Coating

Chemical vapor deposition (CVD) process of parylene coating include:

- Sublimation process: Solid di-para-xylylene will be sublimated to gas phase under 120 degrees Celsius in vacuum condition.

- Pyrolysis process: Di-para-xylylene gas will decompose into reactive monomer after pyrolysis reaction under 650 degrees Celsius.

- Deposition process: Reactive monomer will deposit on the surface of workpiece after entered into deposition chamfer, then polymerized with each other.

Advantages of Parylene Coated Magnet

- Unlike the frequently-used coating for magnet, parylene coating is well suitable for micro magnet.

- Parylene coated magnet is free of pin holes due to the reactive monomer will fall into it during vacuum vapor deposition process.

- Parylene coating is a type of stress-free transparent film.

- Uniformity of coating thickness is excellent.

- Parylene coated magnets have superior high temperature stability and moisture resistance.

- In addition to chemical resistance, parylene coated magnet also can be used in medical field owing to biocompatibility.