Precast concrete is treated as a new generation of building material of construction industry, and precast concrete has been widely applied in Europe, America and Middle Eastern. Shuttering magnet is one the most important accessory to precast concrete system. Shuttering magnet is designed to fix the side rails and blockouts when pouring concrete.

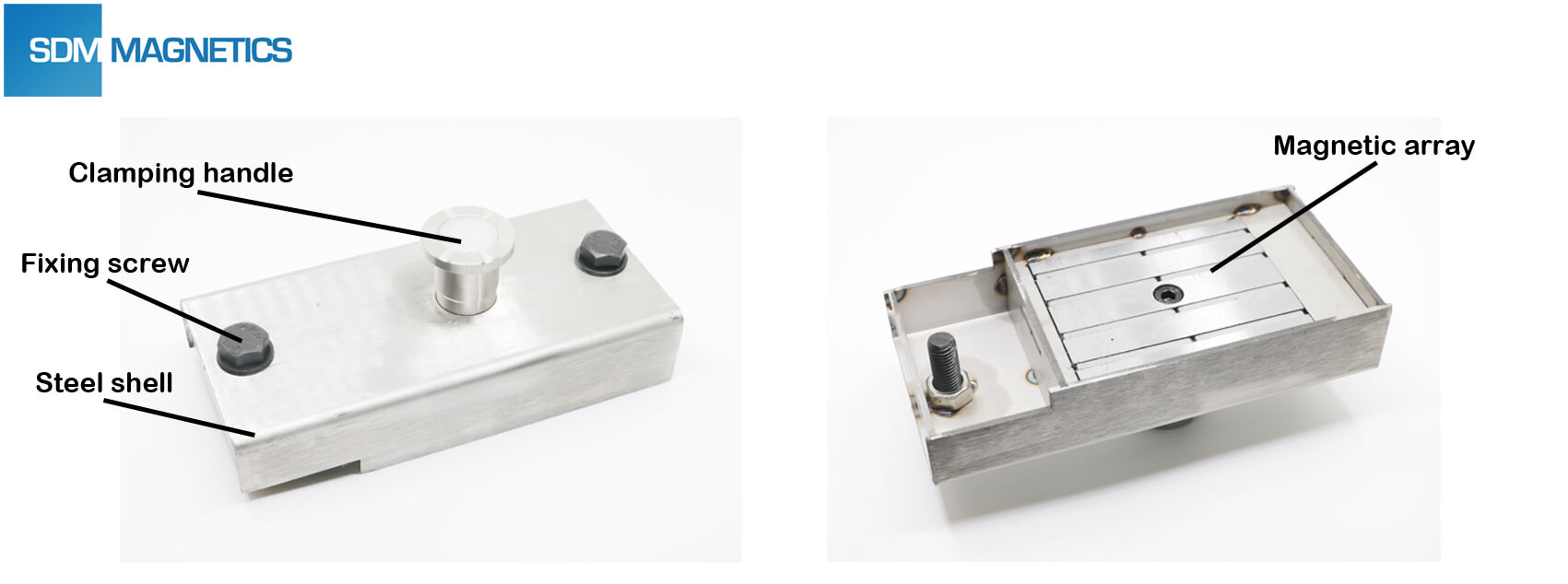

Structure of Shuttering Magnet

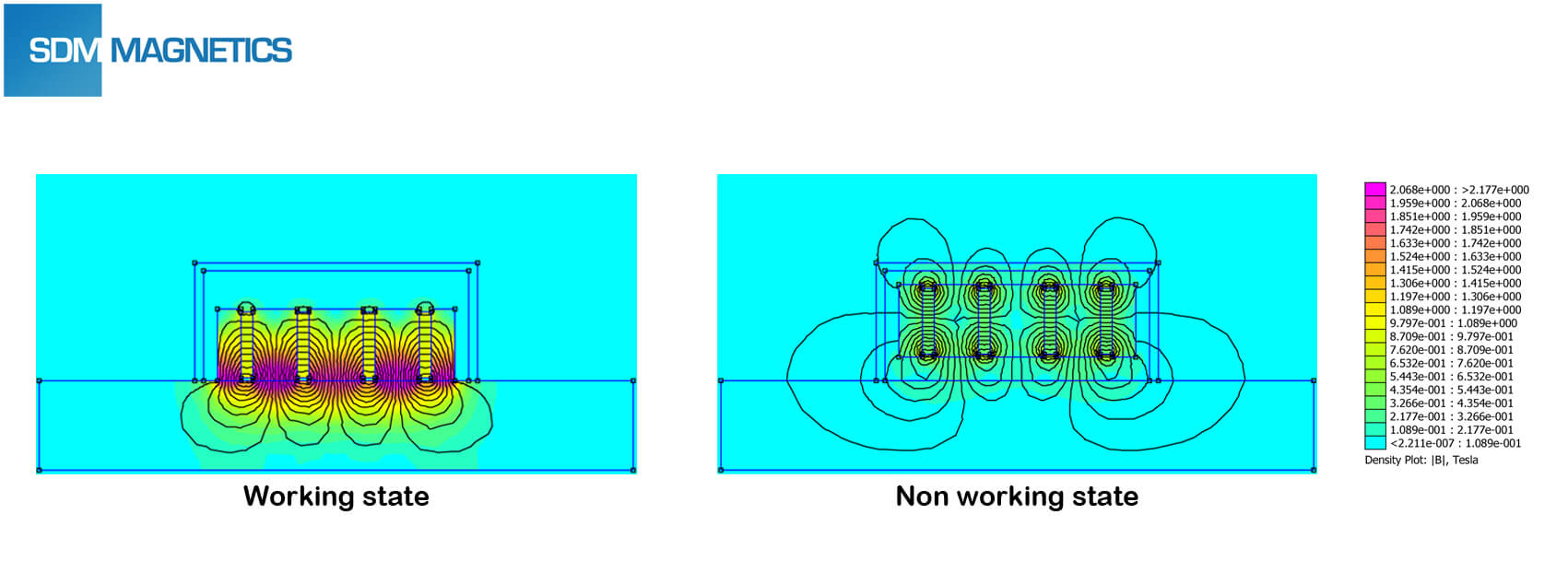

Working principle of Shuttering Magnet

The core component of the whole shuttering magnet is the magnetic array. Sintered Neodymium magnets and steel plates form a special magnetic circuit which provides extremely strong attractive force, and the attractive force is dominated by the air gap. The relevant magnetic circuit as below models shows.

Advantages of Shuttering Magnet

- Very easy and precise positioning, hence reducing complexity and time of installation.

- Excellent applicability, and different concrete products can be finished on same stainless steel board.

- No longer need welding and bolting process which will damage stainless steel board.

- Long operating life and reusable. Payback will be also shorter.

- Significantly improve operating environment and simultaneously ensure the site safety.

Usage Method of Shuttering Magnet

- Place shutter magnets on the specified location of stainless steel board.

- Shuttering magnet will suck on board after pressed clamping handle.

- Use professional crowbar to pry clamping handle, the attractive force will reduce with the increase of the air gap between the magnetic array and board.

- Fixing screws can secure different kind of side rails and blockouts.

Maintenance Method of Shuttering Magnet

- Maximally prevent damage of magnets and avoid external force.

- It is same as permanent magnetic lifter that the working surface of magnetic array should maintain clean and smooth.

- Flexibility of clamping handle will be influenced by invading scrap-iron and concrete.

- Properly rust prevention.

- The Max. Operating Temperature of simple shuttering magnets should be less than 80 degree

- Safety tips should refer to the permanent magnet.

Product Specification of Shuttering Magnet

| Model | Dimension (mm) | Cover material | Net weight (kg) | Attractive forece (kg) | |||||||||

| L | W | H | L1 | L2 | L3 | H1 | H2 | H3 | S | ||||

| SDM600 | 210 | 60 | 40 | 92.5 | 71.5 | 40 | 74 | 65 | – | M12 | S304 | 1.9 | 600 |

| SDM800 | 210 | 62 | 54 | 85 | 85 | – | 88 | 79 | – | M12 | Q235 | 2.8 | 800 |

| SDM900 | 210 | 62 | 54 | 85 | 85 | – | 88 | 79 | – | M12 | Q235 | 3.0 | 900 |

| SDM1000A | 200 | 98 | 40 | 99.5 | 67.5 | 50 | 75 | 65 | 10 | M12 | S304 | 2.8 | 1000 |

| SDM1000B | 240 | 68 | 54 | 90 | 90 | – | 88 | 79 | – | M12 | Q235 | 3.2 | 1000 |

| SDM1800A | 260 | 120 | 60 | 112 | 112 | – | 94 | 85 | – | M16 | S304 | 5.7 | 1800 |

| SDM1800B | 260 | 120 | 60 | 112 | 112 | – | 94 | 85 | – | M16 | Q235 | 6.3 | 1800 |

| SDM2100A | 320 | 120 | 60 | 136 | 136 | – | 94 | 85 | – | M16 | S304 | 7.3 | 2100 |

| SDM2100B | 320 | 120 | 60 | 136 | 136 | – | 94 | 85 | – | M16 | Q235 | 7.4 | 2100 |

| SDM2400A | 320 | 120 | 60 | 136 | 136 | – | 94 | 85 | – | M16 | S304 | 7.5 | 2400 |

| SDM2400B | 320 | 120 | 60 | 136 | 136 | – | 94 | 85 | – | M16 | Q235 | 7.6 | 2400 |

| SDM3000 | 320 | 160 | 60 | 136 | 136 | – | 94 | 85 | – | M16 | Q235 | 10.6 | 3000 |

About Shuttering Magnet Adapter

Angle steel mold or channel steel mold has different bottom margin width, then step size of shuttering magnets may not be suitable for all molds. Shuttering magnets generally utilize customized adapter to adapt to the steel board.

May 14, 2020

Shuttering magnet