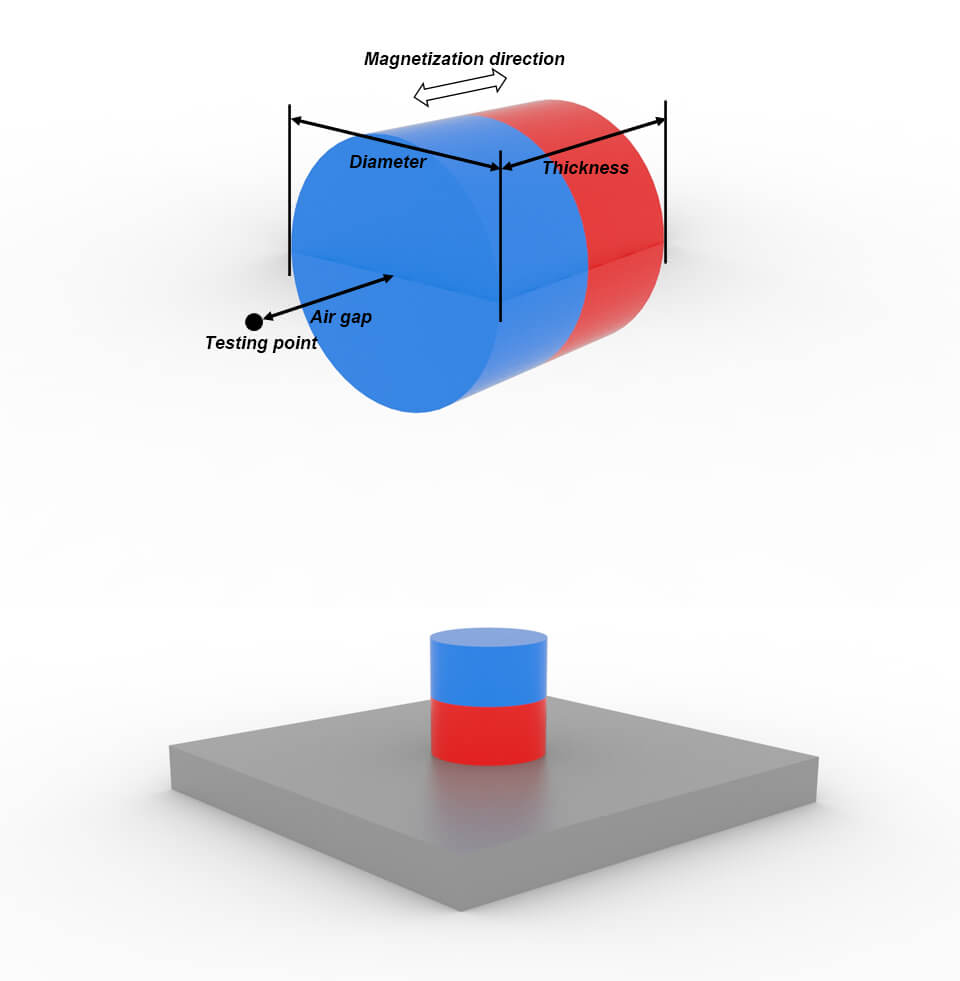

Ceramic magnet is always offering benefits in terms of their matchless cost advantage and high corrosion resistance. Ceramic disc magnet is also measured by diameter (D) and thickness (T) which totally same as Neodymium disc magnet. Ceramic disc magnet can be served in a variety of sizes and it across a series of civilian applications, including the fridge magnet, souvenir magnet, and white board magnets. Besides above conventional scenarios, ceramic disc magnet also can be utilized by sensor, electricity meter, instrument, and medical apparatus.

Ceramic Disc Magnet Calculator

Notes:

- This calculator adapts to non-coating and non-chamfer magnet.

- Gauss value is based on Biot-Savart law and applicable to calculate gauss value of pole face’s geometric center.

- Surface gauss value decreased as the air gap increased, therefore, both encapsulation of hall component and neglected air gap have the significant role on the accuracy of gauss value. We recommend users set the air gap between 0.3 and 0.5mm.

- Measurement repeatability of surface gauss is relatively low even testing point is the geometric center. It must be pointed that surface gauss cannot represent the overall magnetic performance of the magnet in comparison with magnetic flux or magnetic moment.

- Air gap between magnet and steel plate in calculator is 0mm. In reality, even very small air gap will generate dramatic influence on the pull force in both theoretical calculations and the actual measurement.

- Besides magnet’s material, grade, and dimension, pull force is also impacted by steel plate’s material, composition, and surface condition. Steel plate should be thick enough to carry all magnetic flux or result in the low pull force owing to magnetic saturation.

- Above calculation results are only for reference.