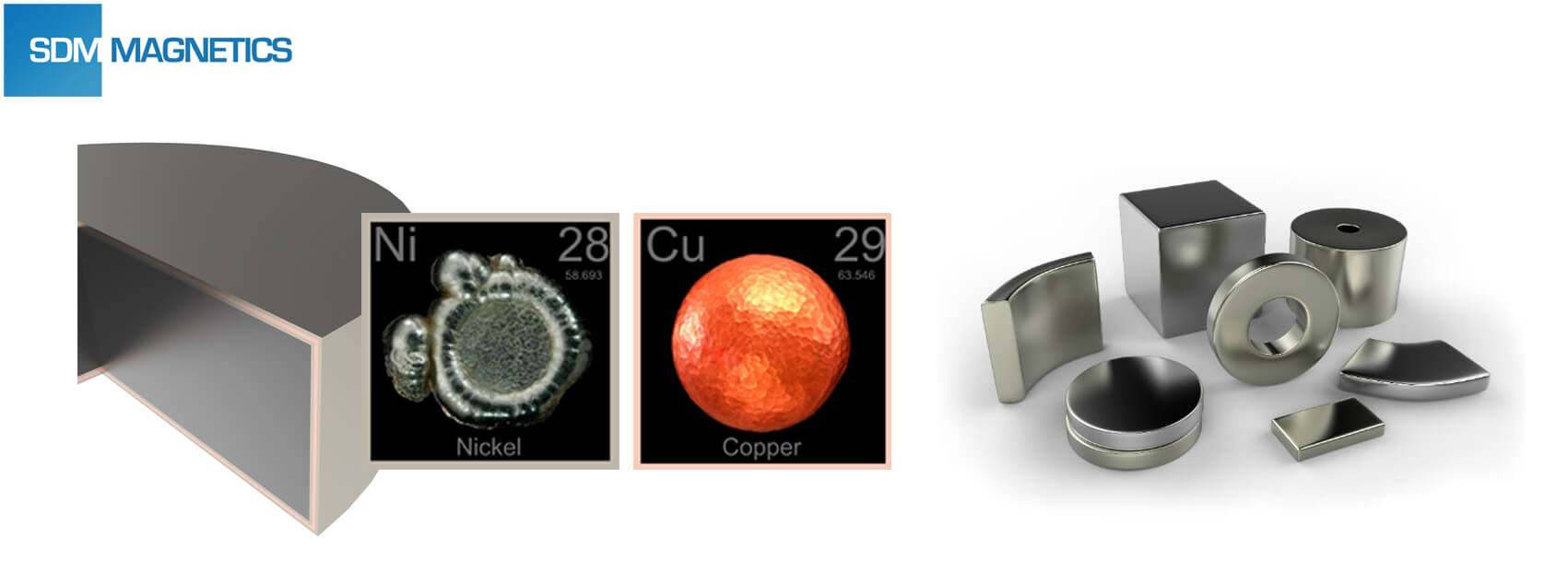

Electroless plating is a process of plating metal by redox reaction rather than impressed current means, in which the workpiece to be plated is immersed in the plating solution with reducing agent that, during catalyzed by workpiece surface, changes metal ions to metal thus forms a deposit on the workpiece. Electroless nickel plating of sintered Neodymium magnet is developed from Ni-Cu-Ni electroplating. Replacing bright nickel electroplating by dense and low porosity electroless nickel plating upon the copper plating can effectively enhance corrosion resistance of magnets. Electroless nickel plating mainly utilize H2PO2– as reducing agent to reduce Ni2+ to Ni, then a small amount of H2PO2– is reduced to elemental phosphorus by hydrogen atom at the same time. Thereby, electroless nickel plating is essentially a nickel phosphorus alloy plating. Electroless nickel plated Neodymium magnet also exhibits preferable chemical stability, hardness, and wear resistance in comparison with conventional nickel plating. In addition, electroless nickel plating has superior dispersibility and makes electroless nickel plated Neodymium magnet available in special shaped Neodymium magnet, micro Neodymium magnet, and high dimensional accuracy Neodymium magnet.