Hard disk drive (HDD) is a kind of data storage device that applies magnetic storage to store information by magnetic material coated rotating disk. Hard disk drive (HDD) has been became the second generation storage device after introduced by IBM in 1956. The solid state drive (SSD) start to hit the market share of hard disk […]

Techtalk

Some Introduction to Parylene Coated Magnet

Parylene is the common name of Poly-para-xylylene which was prepared by the researcher in University of Manchester in 1947. Parylene first applied to U.S military and aerospace industry after Union Carbide prepared parylene thin film by the deposition process. Nowadays, parylene coating are widely used in various areas like parylene coated magnet due to the […]

Some Instroduction to Everlube Coated Magnet

As one of the leading branches in Curtiss Wright, Everlube® is regarded as the leader of functional coating which utilized by Boeing, Airbus, and NASA over the past few decades. As a thermosetting coating, Everlube coating is mainly composed of Polytetrafluoroethylene (PTFE), Molybdenum Disulfide (MoS2), and phenolic resin adhesive. In reality, Everlube coated magnet is […]

Some Introduction to ABS Wheel Speed Sensor Magnet

ABS, also known as anti-lock braking system, is an automotive safety system which avoid the wheels from locking and maintain the adhesive force between wheel and road in maximum value. ABS can calculate the speed, wheel angular deceleration, and wheel slip ratio according to wheel angular speed signal. ABS wheel speed sensor magnet is a […]

About Automotive Water Pump Magnet

Automotive water pump is an essential component in engine’s cooling system. The water pump can ensure the coolant fast through engine coolant circulation line, then take away tremendous amounts of heat generated by the engine. The impeller is a one of the core parts for automotive water pump. Actually, the impeller can be coupled with magnet by injection molding […]

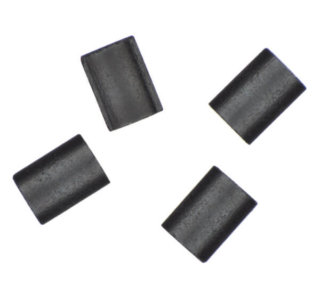

Some Introduction to Rubber Coated Magnet

About Radially Oriented Ring Magnet

Grain Boundary Diffusion (GBD) Technology of Sintered Neodymium Magnet

Application of Vacuum Infiltration Technology in Compression Molded Magnet

The parts are easily have the pores and pin holes in casting and powder metallurgy process. These internal defects will become lasting threats to the part, and may result in the structure failure. For the vacuum infiltration technology, the infiltration agents can be filled into the internal defects under the vacuum conditions. There are about 21vol% voids inside the […]

Metal Injection Molding (MIM) of Sintered Magnet

What is metal injection molding (MIM) process? Metal injection molding (MIM) process is a metalworking process by which finely-powdered metal is mixed with a measured amount of polymer binder material to comprise the “feedstock” capable of being handled by plastic processing equipment through a process known as injection molding. The metal injection molding (MIM) process is already applied in sintered magnet. […]