Brief Introduction of Bonded AlNiCo Magnet

According to the type of raw magnetic powder, the bonded magnet can be divided into bonded NdFeB magnet, bonded ferrite magnet and bonded SmCo magnet in normal circumstance. Have you ever heard the bonded AlNiCo magnet before?

The raw material of bonded AlNiCo magnet:

Based on the standard specifications for permanent magnet materials, the AlNiCo magnet contains many grades, such as AlNiCo 2, AlNiCo 5 and AlNiCo 8. Different grade have different elemental component. For example, there is no Cobalt in AlNiCo 1 magnet, and the AlNICo 8 includes Alumium, Nickel, Cobalt, Copper, Titanium and Iron. It must be said that AlNiCo is an iron-based alloys. The content of iron element in AlNiCo is between 30% and 65%. The raw magnetic powders of bonded AlNiCo magnet are come from AlNiCo 8.

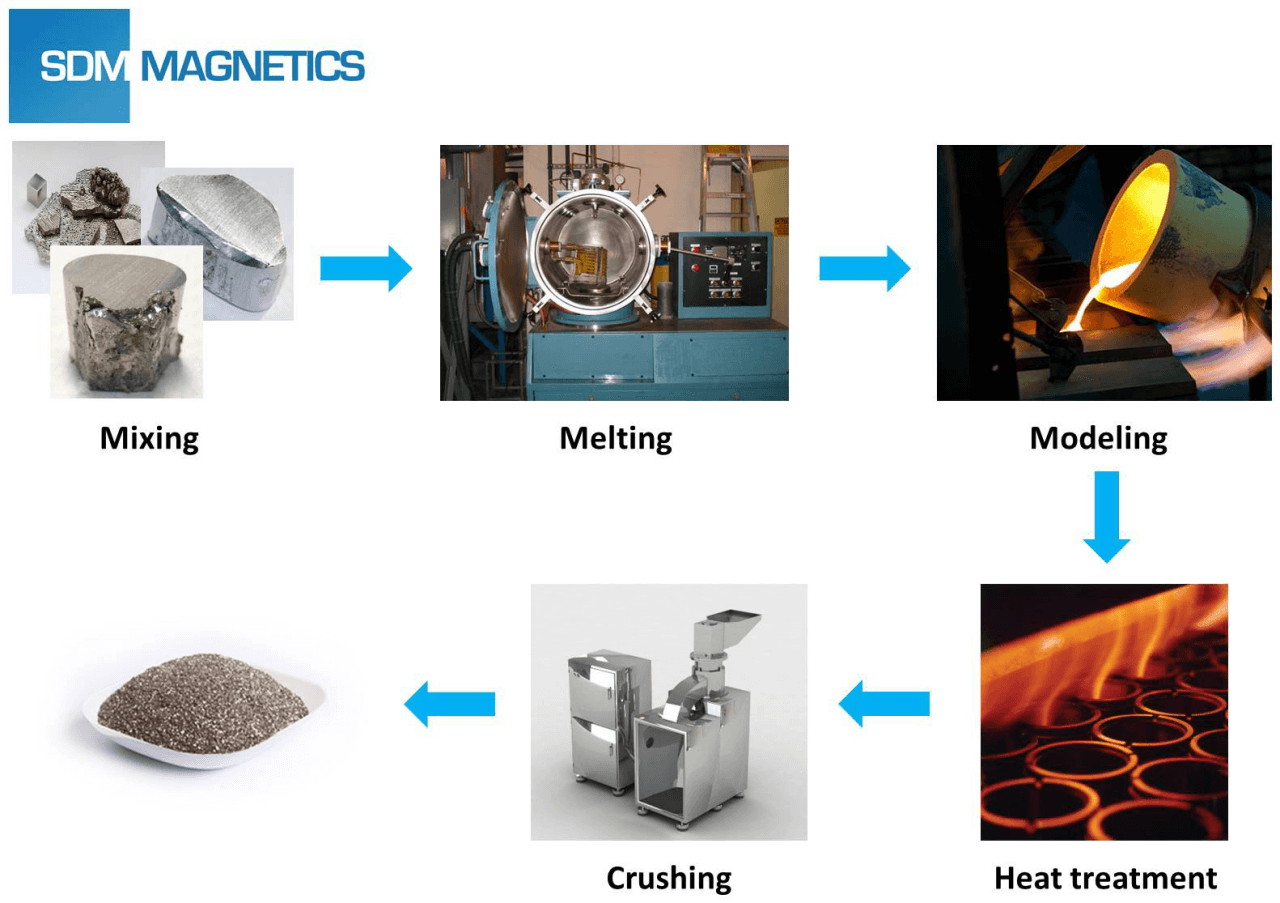

The manufacture process of raw powder for bonded AlNiCo magnet:

Most of steps in the above flow chart exactly the same as the cast AlNiCo’s manufacture. The cast AlNiCo’s green part will be crushed into specified particle size under the protection atmosphere.

Raw powder’s price for bonded AlNiCo magnet:

As the strategic resource, Cobalt’s price always expensive. The Cobalt element’s content in AlNiCo 8 nearly 35%, so the raw powder’s price for bonded AlNiCo magnet also very high. Its price is close to $40/kg, almost reached the level of MQP-B+.

The molding technology of bonded AlNiCo magnet:

Currently, both compression molding and injection molding can be used in bonded AlNiCo magnet.

The binder for bonded AlNiCo magnet:

The binders for bonded AlNiCo are same as the conventional. Both epoxy resin and PA can be applied into bonded AlNiCo magnets.

The magnetic properities of bonded AlNiCo magnet:

For bonded AlNiCo magnet, like simple bonded magnet that magnetic properties hinges on the properties of raw powder and magnet’s loading rate. Higher density increases the magnetics properties of magnet. In order to guarantee the molding, the loading rate of injection AlNiCo magnet is much lower than compression’s, also its performance.

Magnetic properties of compression AlNiCo magnet:

| Grade | Residual Induction

Br |

Coercivity

Hcb |

Intrinsic Coercivity

Hcj |

Max. Energy Product

(BH)max |

Density

(g/cc) |

Temp. Coefficient of Br

%/℃ |

| AlNiCo 7/8 | 3.40kGs

340mT |

0.90kOe

72kA/m |

1.05kOe

84kA/m |

0.88MGOe

7.0kJ/m3 |

5.6 | -0.02 |

| AlNiCo 8/10 | 3.50kGs

350mT |

1.00kOe

80kA/m |

1.20kOe

96kA/m |

1.00MGOe

8.0kJ/m3 |

5.8 | -0.02 |

Magnetic properties of injection AlNiCo magnet:

| Grade | Residual Induction

Br |

Coercivity

Hcb |

Intrinsic Coercivity

Hcj |

Max. Energy Product

(BH)max |

Density

(g/cc) |

Temp. Coefficient of Br

%/℃ |

| PAI-1 | 0.95-1.05kGs

95-105mT |

0.38-0.44kOe

30-35kA/m |

0.63-0.70kOe

50-56kA/m |

0.10-0.14MGOe

0.80-1.10kJ/m3 |

2.75-2.85 | -0.02 |

| PAI-2 | 0.44-0.50kGs

44-50mT |

0.25-0.30kOe

20-24kA/m |

0.63-0.70kOe

50-60kA/m |

0.03-0.04MGOe

0.25-0.35kJ/m3 |

2.00-2.30 | -0.02 |

Max Operating Temperature of bonded AlNiCo manget:

The Max Operating Temperature of cast AlNiCo and sintered AlNiCo can reach 450~550 degree Celsius, so someone may would consider that the Max Operating Temperature of AlNiCo magnet maybe higher than the simple bonded magnet, but it should be noted that the Max Operating Temperature of AlNiCo magnet also depend on its binder.

Coated or Non-coated when the magnets shipped?

Unlike cast AlNiCo or sintered AlNiCo, the compression AlNiCo magnet cannot reach the full-density. In order to avoid magnetic particles dropped during working that we suggest you to coating magnets. Both black epoxy resin coated and grey epoxy resin coated.

Magnetized or Non-magnetized when the magnets shipped?

Both can meet.

Application of bonded AlNiCo magnet:

- Magnetic driven bearing of power energy measuring instrument.

- High stability magnetic sensor.

- Automatic control surveying instrument.

Why choose bonded AlNiCo magnet?

The raw material of bonded AlNiCo magnet comes from the cast magnet. It can keep the outstanding temperature stability of cast magnet. Its magnetics evenness and anti-magnetization ability is also excellent.