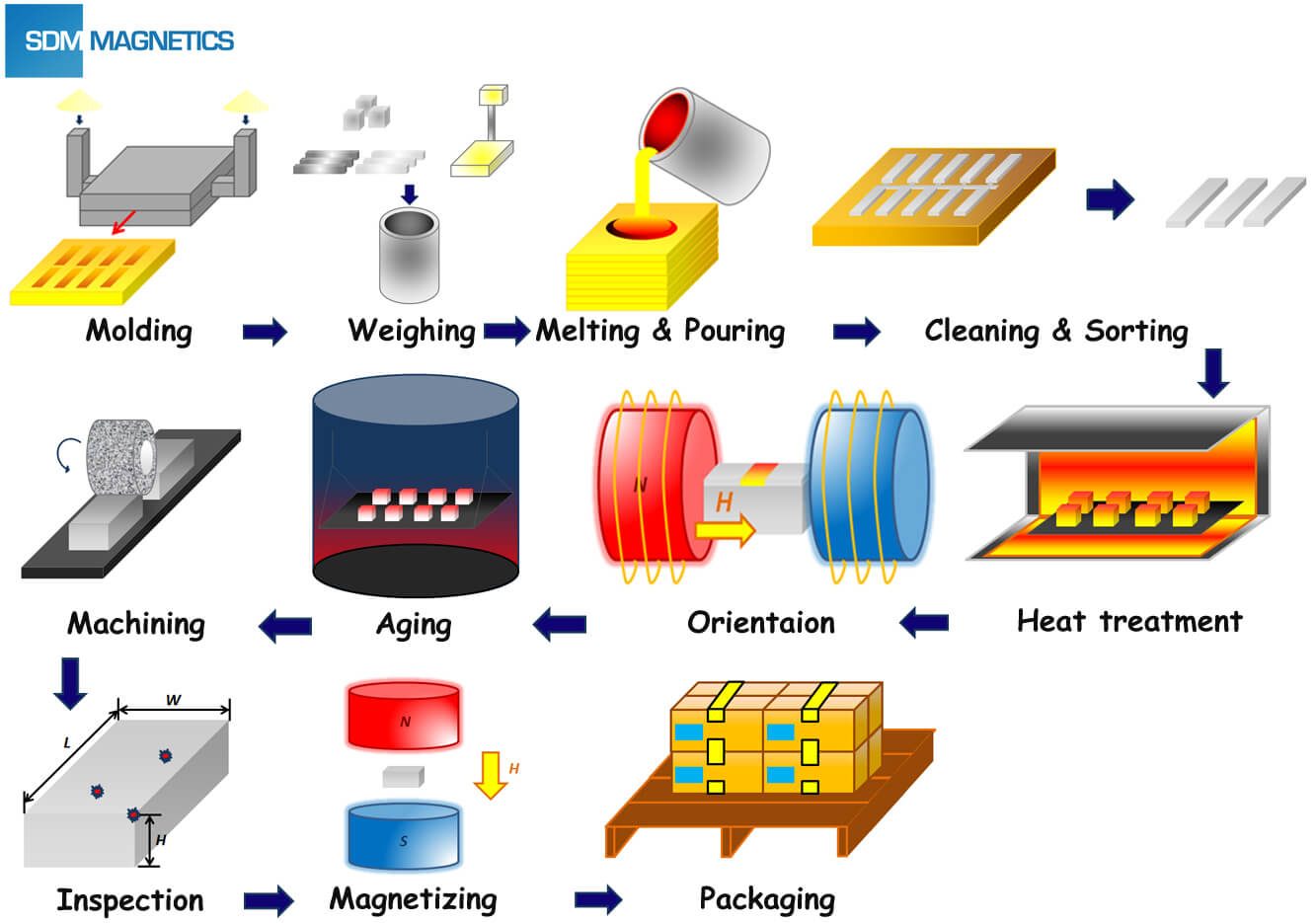

The flow chart of Alnico casting magnets

The Alnico casting magnet can be divided into vacuum casting magnet and simple one. For simple Alnico casting magnet, the manufacturer will use resin-coated sand as raw material of mold. The molding process is relied on core shooting machine. Customer need to bear tooling cost when there’s no suitable mold. For vacuum casting magnet, the mold is made by hand. The operators fill bauxite into the tooling, and then put it in furnace.

Weighing

Alnico contains many different grades. The classification standard of Alnico magnet includes composition, magnetic properties and structural morphology. The weighing process is very important to ensure the magnet have accurate composition. Most of manufacturers use runner material or recycle material to reduce raw materials cost. The raw material need free of oxidation and impurities.

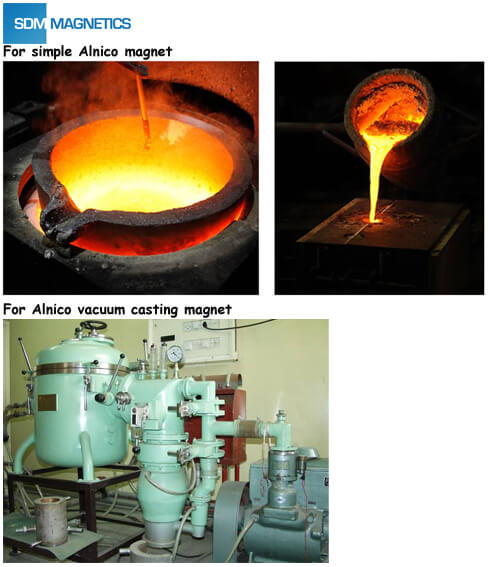

Melting & Pouring

The melting process need to ensure raw material completely melted. The melting and pouring process of simple Alnico casting magnet are done in the air. The facility requests for vacuum Alnico casting magnet are relative high. The directional crystallization device is very important for the manufacture of desirable structural morphology and high properties casting Alnico magnets.

Cleaning & Sorting

The sand cleaning process will make the blank of Alnico casting magnet separate from molding sand. The manufacturer can identify its quality and composition by macro state of blank.

Heat treatment

The heat treatment process also has significant influence on the properties of end product. The heat treatment process of Alnico magnet can break up to blank’s annealing, preheating and solution treatment. The annealing can reduce hardness to guarantee the de-burring process. For large size magnets, the cracks can be avoided after preheating.

The single solid solution phase will be formed after high temperature solution treatment. The suitable temperature, time and reducing atmosphere will help Alnico casting magnets avoid oxidation and deformation.

Orientation

The Alnico casting magnet should have a rapid quenching after taken from solid solution, then start the orientation heat treatment. The orientation magnetic field must big enough. The high cobalt content magnets will need an isothermal treatment under the magnetic orientation.

Aging

The three step aging process will enable the ferromagnetic phase α1 grow to suitable size. The aging process takes more than 25 hours. The magnet will have magnetism after aging process, and the manufacturers need to demagnetize them before machining.

Machining

Alnico casting magnets are often applied to aerospace and military industries, and its dimensional and geometrical tolerance very strict. The subsequent machining technology would be particularly important for Alnico casting magnet.

February 8, 2022

Hello, i’m Sumero Lira from Neotenia LTD. I would like to ask permission to use these images in a, italian middle school digital textbook, citing you as source. Many thanks

best regards