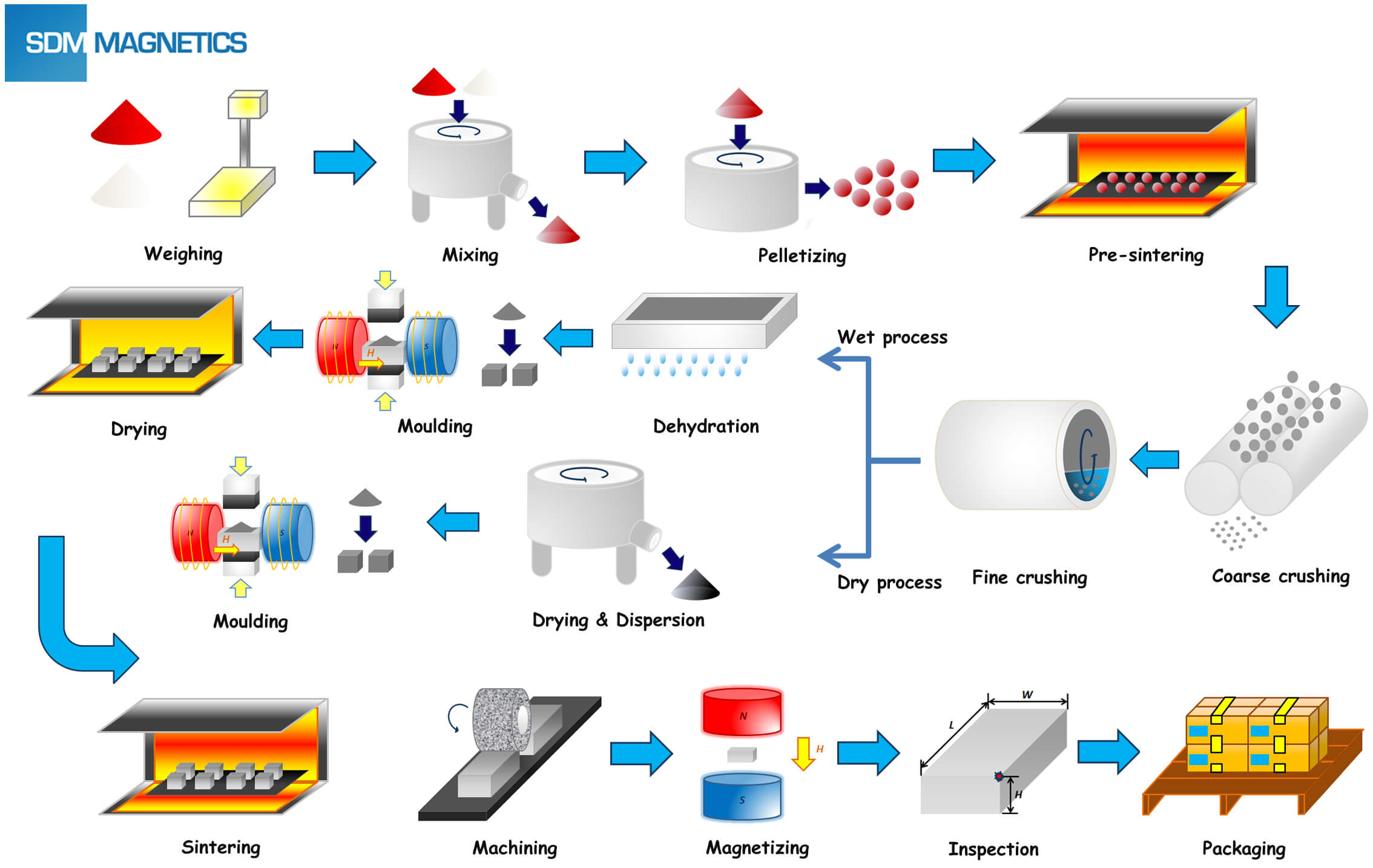

The flow chart of ferrite magnets

Weighing & Mixing

The raw material of ferrite includes main raw material, additives and flux agents. Fe2O3, BaCO3, SrCO3 and CaCO3 are main raw material of ferrite. The weighing process need to follow the formula strictly, or cannot get the desirable magnetic properties. The raw material will be mixed in specialized equipment after weighing process. The component homogeneity bases on mixing process. There are several factors affect the component homogeneity of mixture.

Pelletizing

In order to ensure the solid-phase reaction process, the mixtures need to pelletize before pre-sintering. The solution will spray to mixture during pelletizing process. The size of pellet material will influence the pre-sintering time.

Pre-sintering

The purpose of pre-sintering is fully guaranteeing the solid-phase reaction of raw material, and most of raw material will turn into ferrite phase after pre-sintering. The pre-sintering process will also improve deformation, shrinking and density. The pre-sintered powder can be used as the raw material of sintered magnet, bonded magnet and absorbing material. Most of ferrite manufacturers purchase pre-sintered powder directly now.

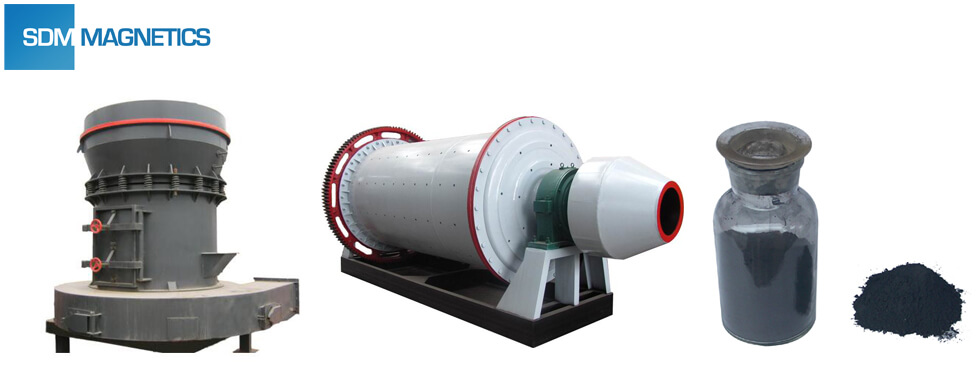

Crushing

The pre-sintered material will crush into fine powder in this step. The crushing process will be finished by ball mill equipment. The milling medium is steel ball and water.

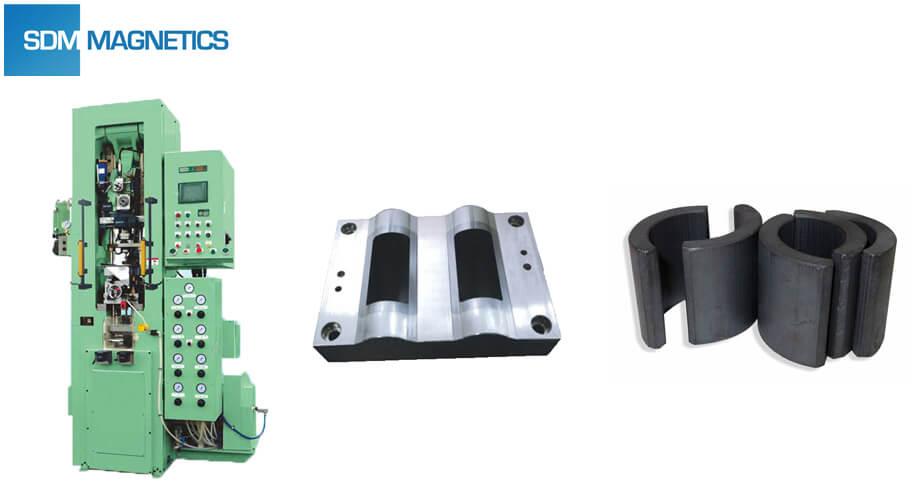

Moulding

The ferrite magnets can be divided into isotropic and anisotropic base on traditional classification method. The ferrite also fall into wet process and dry process by theirs moulding mode. The technology intensive of moulding process is very high.

Sintering

Like other types of sintered magnet, the sintering step also very important for ferrite magnets. Firstly, the sintering process will affect the microstructure, and further influence the magnetic properties of ferrite. The unreasonable sintering parameters will cause magnet cracks, bubble and deformation.

Machining

The machining method of ferrite magnet contains grinding, polishing, cutting and punching. It is worth mentioning that the ferrite is insulating materials, so the manufacturer will use grinding wheel in cutting step.

August 14, 2017

I want make new manufacturing setup plz i have need help so my name is Mubasher ilyas form Pakistan already i have manufacturing of electric fans by name of Sky fan Gujrat Pakistan.

Plz you contact at watts’up number 00923137808482 or

You can contact also at my email adresss :

mubasherilyas82@gmail.com.

July 2, 2019

Dear Sir,

I can helpyou to manufacture these type of powder and magnets .

March 27, 2020

Hy kindly share with me your email address please also contact usmanhanif567@gmail.com

February 7, 2021

Sir, i am interested in manufacturing plant for hard ferrite magnet.plz share your email or contact number.

June 24, 2018

Ferrite magnet manufacturer ahmedabad gujarat mobile number 09879052939 pizza halpi

August 27, 2019

want make new manufacturing setup plz i have need help so my name is Mubasher ilyas form Pakistan already i have manufacturing of electric fans by name of Sky fan Gujrat ahmedabad

Plz you contact at watts’up numbers 9879052939

You can contact also at my email adresss : nnengneering99@gmail.com

August 21, 2018

I want make new manufacturing setup for N42 magnet. plz i have need help so my name is Ahmadi form iran

Plz you can contact also at my email adresss :

tejarisazi2020@yahoo.com

January 13, 2019

O material usado nestes imãs é o mesmo dos trafos de ferrites das fontes chaveadas e inversores? Obrigado.

August 5, 2020

Hi

I wanna a grinding machine for ferrite magnets.

July 3, 2022

Hello Babak,

Do you produce ferrite magnets and have other pieces of machinery?

September 3, 2020

can you pls send me details and cost for manufacturing setup for ferrite magnet at medium production capacity for india.

September 29, 2020

Hi team,

I am interested in setting up a magnet production plant in India. Please share your email Id (preferable) or contact number so that we can discuss further.

September 24, 2021

Hi team,

I am interested, Please share with me the cost for manufacturing setup for ferrite magnet at medium production capacity in India. Please share your email Id (preferable) or contact number so that we can discuss further.

November 24, 2021

Please, I am interested in establishing a ferrite magnet factory with a medium production capacity in Egypt. How much will it cost?