According to its molding technology, the bonded magnet can be mainly divided into compression, injection, extrusion and calendar types. The compression molded magnet is the most widely used among them. NdFeB compound play an extremely important part in the manufacturing process of compression molded magnet.

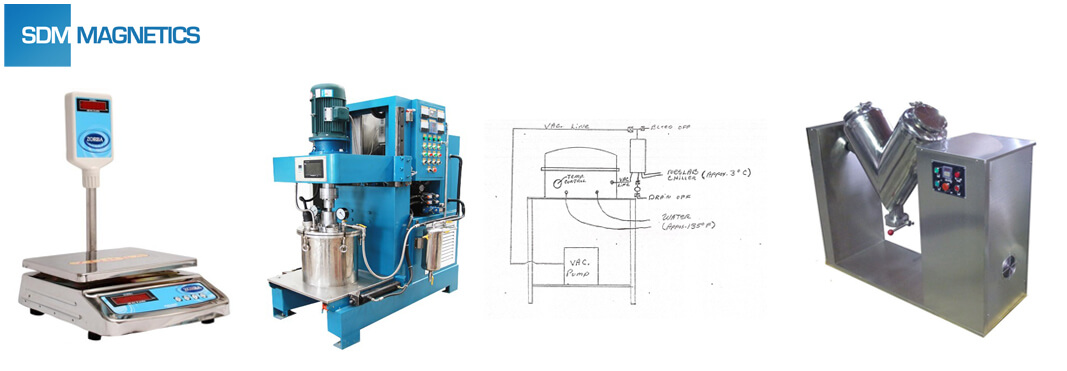

The preparation of NdFeB compound

The first step for the preparation of NdFeB compound is weighing the NdFeB powder, epoxy resin, acetone and lubricant. The usage of epoxy resin usually around 2.0wt%, then dissolve the solid epoxy resin in acetone to effect a binder solution. The mixing process will achieve the granulation of NdFeB compound. The manufacturer will add lubricant (Zt-St) to NdFeB compound to ensure the mold release property after mixing step.

The parameters of NdFeB compound

- Magnetic properties;

- Particle size distribution;

- Flowability and apparent density.

- Microstructure.

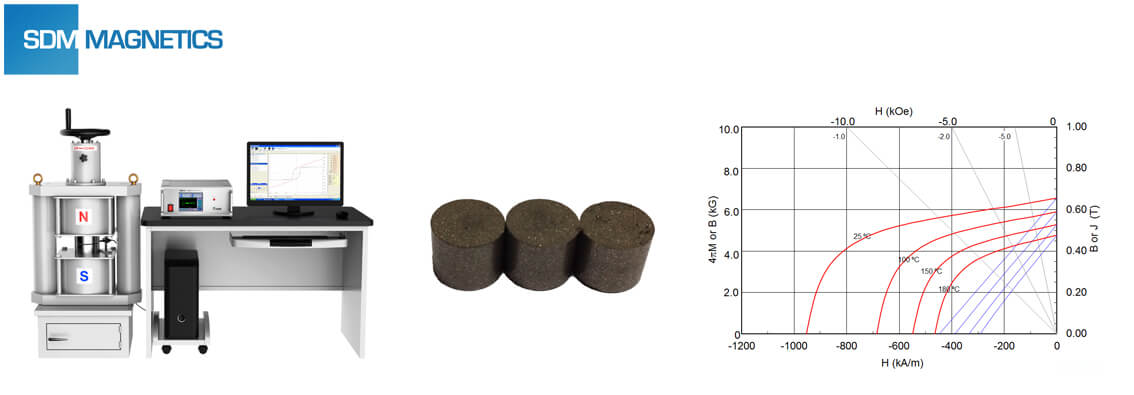

The magnetic properties of NdFeB compound

In generally, the density of compression magnet is between 5.98 and 6.00g/cm3, so the density of column sample will be also kept in this range. The operator can check the main values of NdFeB compounds on hysteresisgraph.

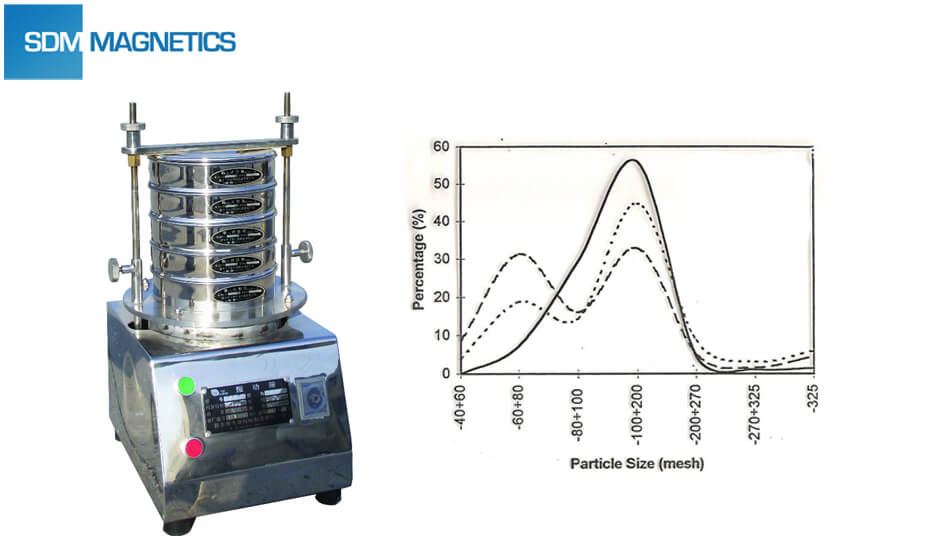

The particle size distribution of NdFeB compound

The particle size distribution is a critical parameter for NdFeB compound. The manufacturer will adjust the particle size distribution base on the shape and dimension of magnet. Many people think that the suitable particle size distribution is the precondition of get high density and high strength magnet.

The flowability and apparent density of NdFeB compound

The flowability and apparent density of NdFeB compound have great influence on its subsequent molding process. The outstanding flowability will fully ensure the NdFeB compound fill into die cavity, and the unit weight of magnet will also be guaranteed. As the labor cost increases, the automation equipment is imperative in magnet industry. If manufacturer can control magnet’ unit weight during molded process, the automatic unloade technology will be smoothly realized.

The ideal apparent density will give NdFeB compound much lower pressing stroke, then we can get higher density with smaller molding pressure. The material use and lifetime of mold will also be optimized.

The microstructure of NdFeB compound

According to some researches and experiments, the microstructure affect largely on the flowability and apparent density of NdFeB compound. How to get NdFeB compound with excellent microstructure will continue to be the challenge of compression molded magnet.