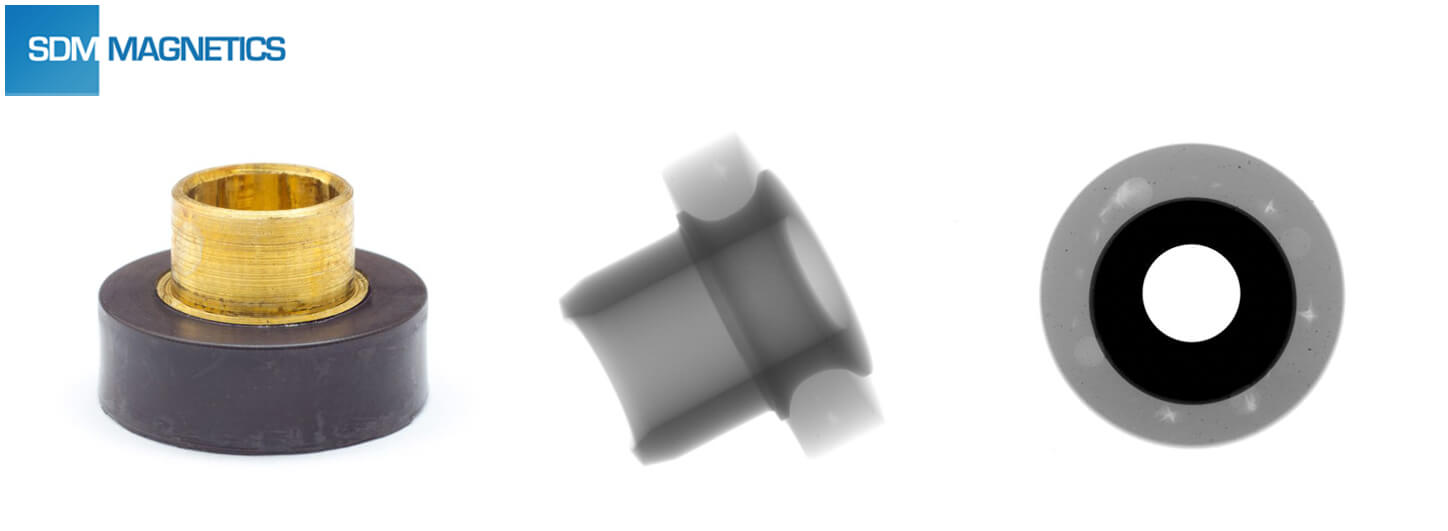

Injection molded magnet were already applied into motor and sensor application for several years. The injection molded rotor assemblies, insert molded magnetic components and over-molded magnetic components has attracted increasing attention from automotive and electronic industry.

Unlike the compression molded magnet, the density of injection molded magnet always fairly close to its theoretical density. For injection molded magnet, the gap between actual and theoretical density means that there are voids in the magnet. The manufacturers called them internal defect.

The potential hazards of internal defect in injection molded magnet

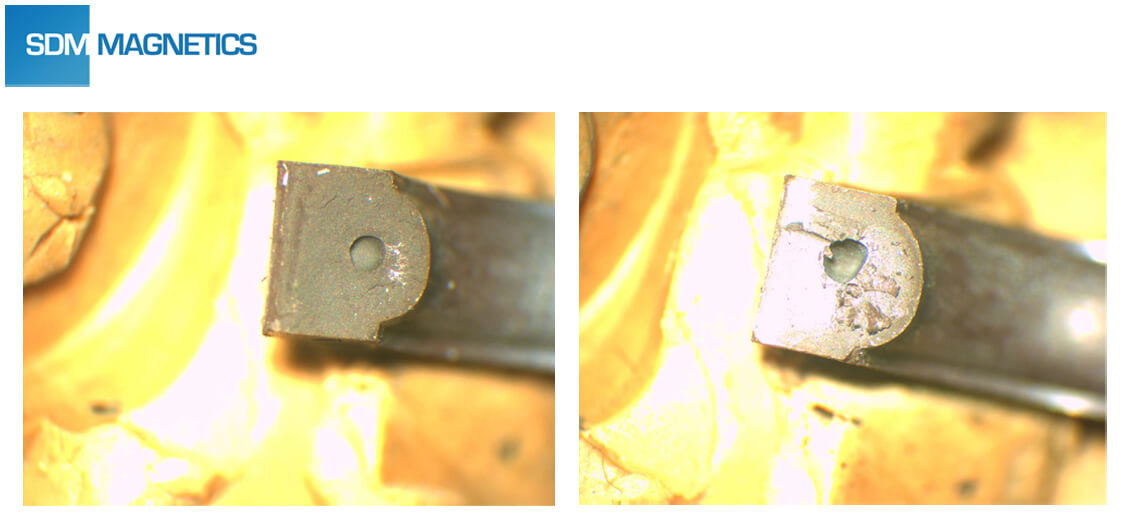

The internal defect will affect the dynamic balance of injection molded magnet under the high speed application. Insert molded magnetic components were usually used as the speed sensor of power tools. The rotational speed of power tool can reach 40000RPM, then the defective magnets will be broken.

The traditional testing method for internal defect of injection molded magnet

The manufacturers will use destructive test to confirm whether exist internal defect in injection molded magnet or not, then adjust the parameters of injection molding.

Unconventional detection method for internal defect of injection molded magnet

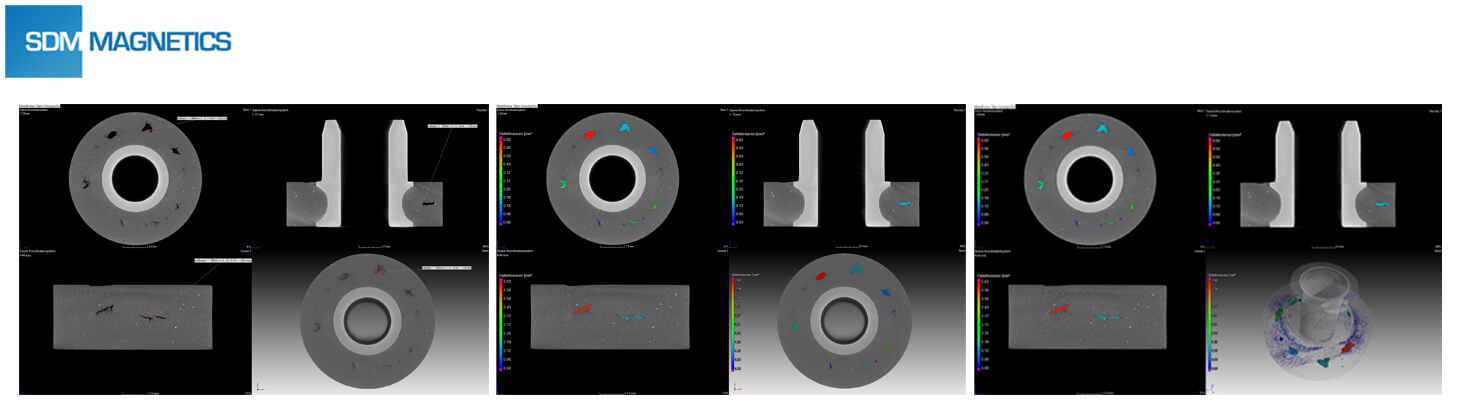

The X-ray technology can be used for defect detection of various parts. The distribution of internal defect can be shown by X-ray technology.

Like X-Ray technology, the CT scanning is also one kind of non-destructive testing for parts. The CT scanning can quantitative analysis the internal physical characteristics and mechanical properties.