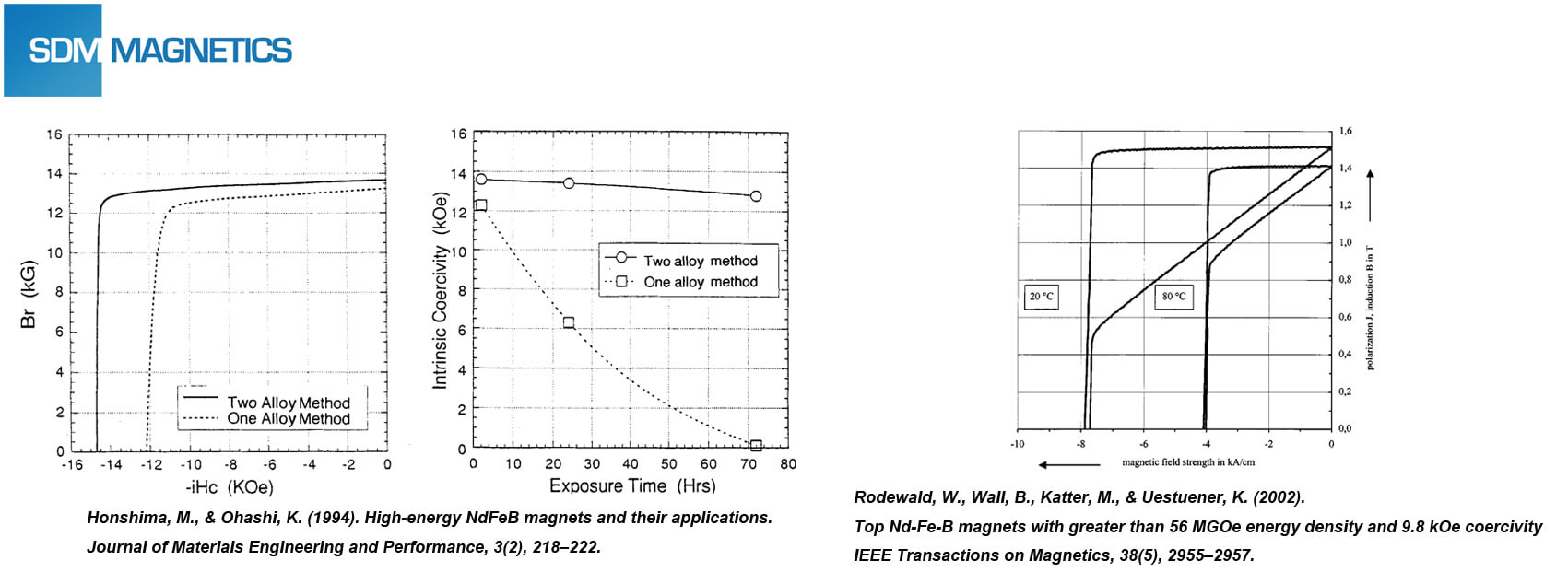

Regular sintered neodymium magnet is fabricated by single alloy technology, and that means manufacturers just need to melt one master alloy from the beginning. In order to enhance the magnetic properties of the magnet, some beneficial elements will be added to master alloy. Some of elements enter main phase to regulate the intrinsic magnetic properties of the hard magnetic phase, and other elements will be served to improve the grain boundary structure.

Dual-alloy technology should melt two master alloys to make sintered neodymium magnets. Two master alloys mixes together according to the certain proportion after crushed into coarse powder. Thus followed by jet milling, pressing and sintering.

Classification of Dual-alloy Technology

- Grain boundary diffusion technology.

- Single main phase and auxiliary phase alloy. The auxiliary phase alloy will serveas grain boundary phase to improve the comprehensive performance of the magnet.

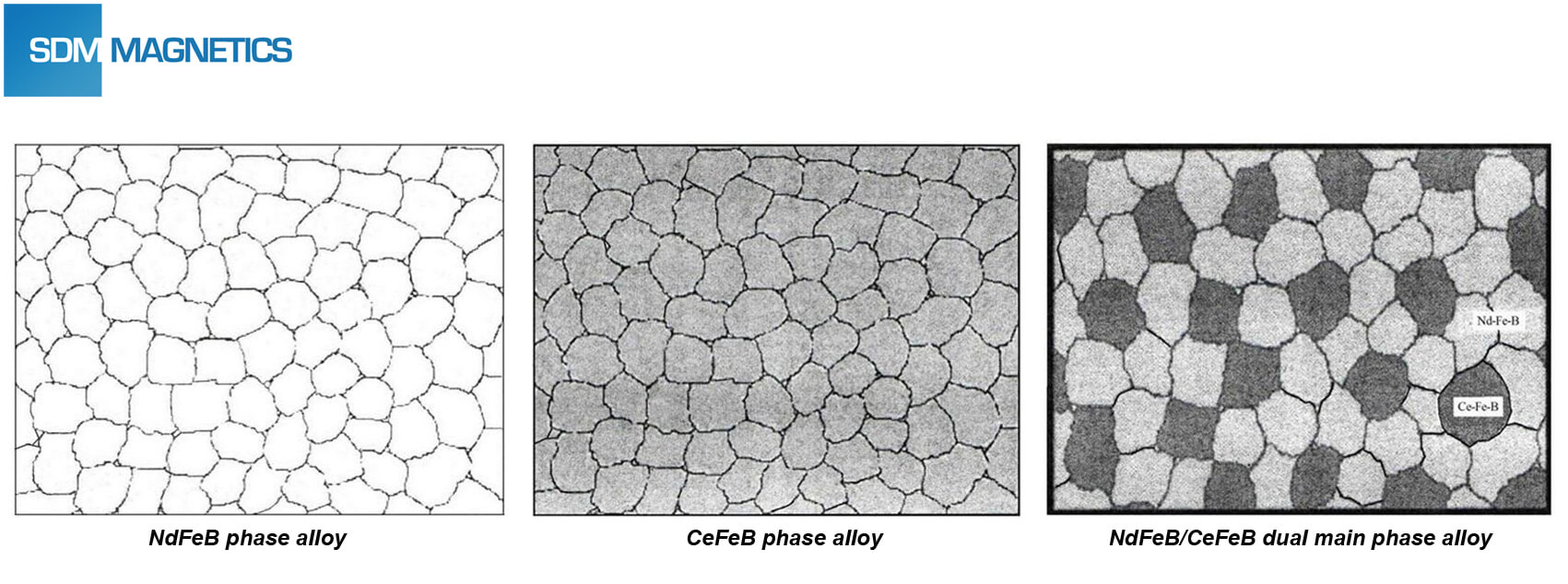

- Dual main phase alloy. The main dualphase neodymium magnet has two different kinds of main phase grain, includes NdFeB + NdFyFeB alloy and NdFeB + CeFeB alloy.

NdFeB + NdDyFeB dual main phase alloy is primarily for enhancement of intrinsic coercivity, and NdFeB + CeFeB alloy can help cerium and lanthanum to achieve reasonable use. Many studies indicate that NdFeB + CeFeB dual main phase alloy can dramatically reduce material cost while still being favorable magnetic performance.